The electrical testing equipment makes it possible for Multi-Contact to perform tests in-house with applied current of up to 3000 A or for partial discharges of up to 100 kV. "This investment allows us to subject our products to a wide range of tests, many that even exceed the requirements laid out in testing standards," explains Michel Schmitt, head of the Railway Technology Market at Multi-Contact. "The goal of all of this testing is to develop products that are even more compact, more powerful, and more durable."

With over 40 years of experience in the railway technology sector, Multi-Contact places its focus squarely on its modular connector systems. "In carriages and locomotives, we need solutions to reduce the time required for maintenance and repair work. Interfaces must be able to be connected and disconnected extremely quickly in order to prevent extended downtimes or train cancellation, for example," Schmitt continues.

Multi-Contact sees itself as a development partner for the industry. Its expertise in a wide range of areas is also tied in with the railway industry and allows the company to develop interface solutions that are perfectly tailored to the application in question. The patented MULTILAM is the heart of the MC product range. This contact technology ensures efficient energy transfer with low performance loss and thus a long product service life.

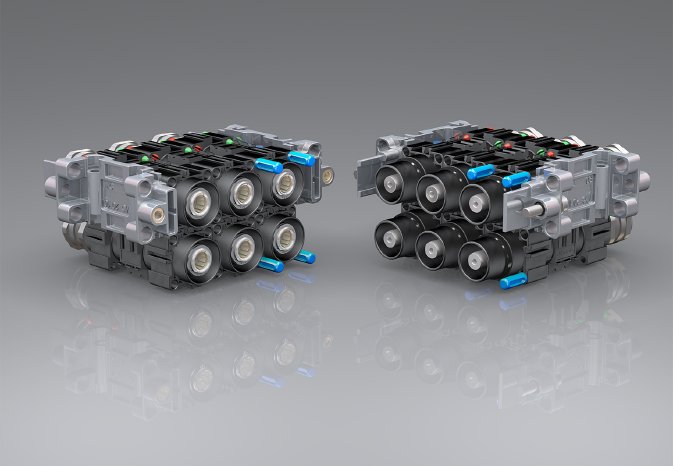

Thanks to their compact, modular design, the power connectors from the MPC series are ideal for creating solutions for railway rolling stock. Modular Power Connectors allow engineers to create connections easily and safely for intercar couplings, traction converters, inverters, or batteries on the roof and under carriages, as well as to traction motors.