Electrifying mining fleets not only reduces emissions but also cuts down on noise pollution and improves the health and safety of mine workers. At present, just 0.5% of mining equipment is completely electrified. Haul trucks — the heavy-duty vehicles that transport ore from the rock face to the dump point — use more energy than any other part of a mining fleet, making them a prime candidate for electrification.

Heavy mining vehicles require high charging power to charge their large-capacity batteries, making them challenging to electrify reliably. And this high power must be transmitted in the shortest possible time to ensure that the mine’s expensive equipment comes as close as possible to continuous use.

“Any charging solution capable of supporting the mining industry must withstand harsh and rugged mining environments. To guarantee uninterrupted charging cycles, the seals and touch protection must keep the contacts clean from water and dust. The reliability and high number of mating cycles of our robust charging connectors guarantee a long service life even in the harshest environments. This ensures virtually no maintenance, and will significantly reduce costs for our customers across the complete product lifecycle” said Alain Schierenbeck, Business Development Manager Charging Solutions.

Stäubli has been in exchange with leading mining companies for years and has therefore continuously developed the Quick Charging Connector System to fulfill the needs of mine operators. The company’s MULTILAM technology ensures a reliable electrical connection and guarantees steady, fast charging.

The QCC-5000 fast charging connector system has been further developed specifically for the mining industry to electrify fleets and accelerate the transition to zero-emission mining operations. The Stäubli system allows vehicles to mate with a charger automatically, without the driver leaving the cab, which enables fastest connection times and avoids the necessity of the operator to come near the high current.

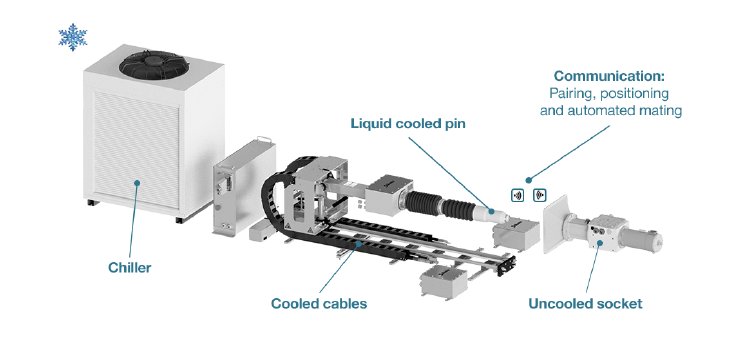

Higher charging power is all about properly managing heat. By cooling its cables and the charging pin and verifying performance in extensive test sessions, Stäubli has achieved 7.5 MW charging with up to 4,250 A of continuous current and 5,000 A peak at 1500 V DC.

With safety in mind, the automated connector on the QCC-5000 is IP55 qualified, with ingress protection from water and dust. The system only reveals the charging contacts at the end of the connection process when the pin and socket are fully connected. Current manual systems feature unprotected contacts. That makes them more prone to failure in demanding mining applications and exposes the workforce to higher risks.

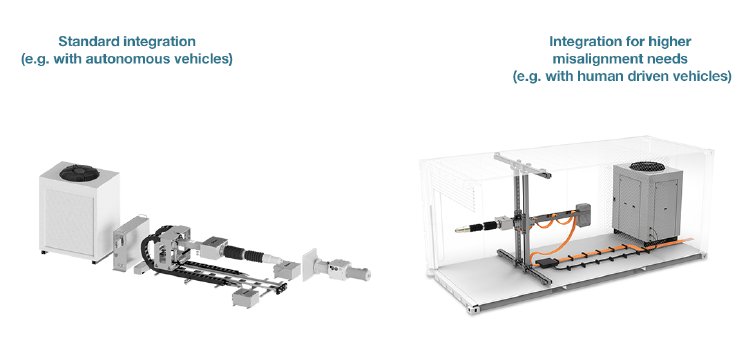

One of the key elements that makes the QCC-5000 stand out is how it combines charging power, safety, and automation possibilities. Using an automated connection device increases operational safety in mines and means that drivers no longer have to get out of their vehicle to initiate the charging process. Depending on the application, vehicle type and general customer needs, the QCC-5000 system offers a variety of integration possibilities: with a standard Stäubli guiding system, mounted to a robot arm or even fully customized solutions. Furthermore, the system is fully mating compatible with the already existing, tried and tested QCC-1500 allowing to use the same interface for multiple charging power levels.

To achieve interoperability within the mining fleet, a charging solution must follow international standards. Stäubli champions compliance with these standards, and the Quick-Charging Connector System built for the mining industry aligns with the SAE J3105/3 electric vehicle charging standard. This open standard, encompassing the design of charging pins and sockets, paves the way for various suppliers to provide compatible solutions.

The system is designed to ensure a well-defined number of low-resistance contact points which enables continuous contact with the contact surface, resulting in a low and constant electrical resistance at the contact points.