Cleaning and disinfection in one step

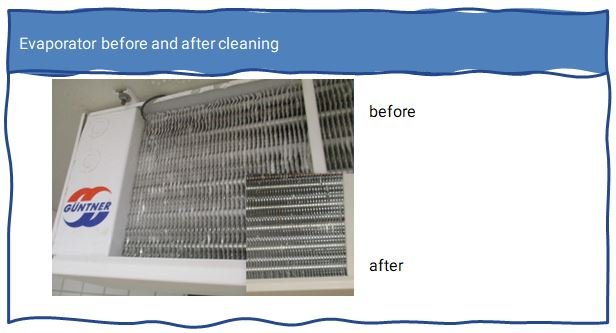

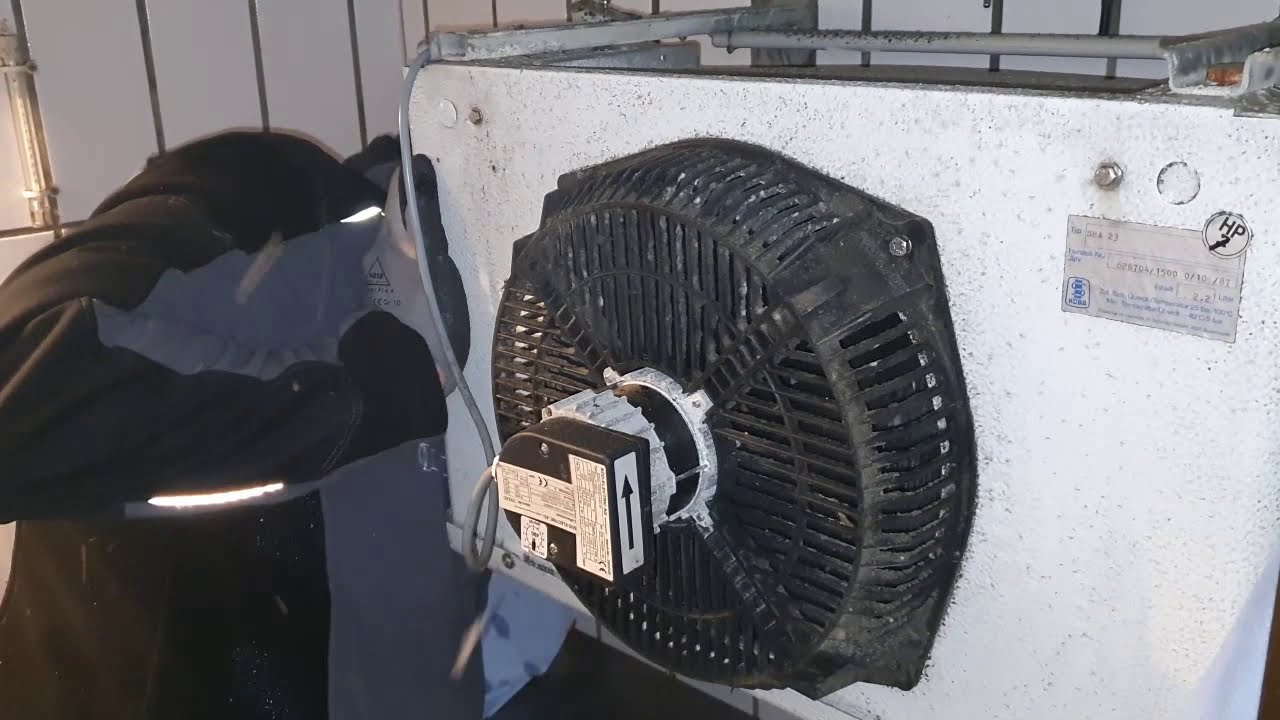

Evaporators and heat exchangers in general are often in use for decades, and in confined conditions. Cleaning was previously often difficult or almost impossible. Contamination residues have therefore partly penetrated the surfaces. The use of the JetBoy now also offers excellent cleaning and disinfection possibilities. Cleaning and/or disinfection with the JetBoy is also possible without any problems with older evaporators and under difficult conditions. In addition to the advantages in terms of hygiene, cleaning with the JetBoy also reduces energy consumption.

Two in one device:

In a second version, JetBoy is available as a multifunctional device. The JetBoy can be switched over to the use of dry ice. This requires a CO2 riser pipe bottle from which liquid CO2 is fed to the JetBoy. The liquid CO2 is converted into dry ice particles in the blasting pistol. To increase the performance, a cold-stable liquid can also be added to the jet. This increases the cleaning effect and creates a rinsing effect with which surface contamination can be better dissolved and removed. The compressed air for the JetBoy is generated by a small electric compressor, which can be used inside buildings without any problems.

mycon offers the JetBoy for rent or purchase. The rental fee for a test of the JetBoy will be credited in full when purchasing a device.

Kipp Umwelttechnik, sister company of mycon offers the use of the JetBoy as a service with a guarantee of success and security for the customer: No success, no billing of the performance.

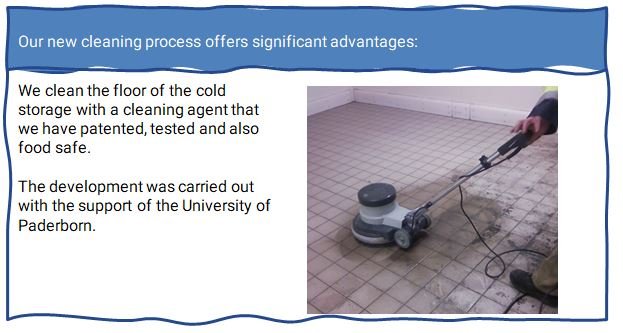

Together with mycon GmbH and its sister company Kipp Umwelttechnik GmbH, develops a process / cleaning agent for cold storage cleaning, a complete package is available for all cleaning operations in the cold storage sector. Advantages: Time savings + energy savings. mycon GmbH provides equipment (purchase or rent) and operating materials, Kipp Umwelttechnik GmbH offers the services. The cold storage can remain in operation during cleaning. The cleaning process + operating resources have been tested and officially certified for use in the food industry by a well-known certification company.

The necessary cleaning of the cold storage takes place at certain intervals, depending on the degree of contamination and requirements (e.g. internal and external audit).

Up to now, the cleaning of the cold storage rooms has been done by moving the goods to a rented refrigerated container for several days, bringing the cold storage room up to working temperature by switching off the cooling and opening the doors, so that it can be cleaned afterwards. This conventional procedure usually takes up to 8 days.

Expenses so far:

- Costs for renting a refrigerated container (up to 8 days)

- Additional energy consumption for the refrigerated container and noise pollution from the refrigerated container's aggregates

- Additional personnel costs due to the relocation of chilled goods

- Bring the deep-freeze warehouse to ambient temperature

- Personnel costs for cleaning the cold store

- Costs for cooling the frozen food storage to storage temperature (e.g. -25°C)

- Put frozen goods back into storage

- Personnel expenditure altogether approx. 40 hours

The scope of this industrial cleaning also includes the gentle and environmentally friendly cleaning of the evaporators of the cooling units.

Our solution - your advantages:

- Cleaning takes place without switching off the cooling

- No need to remove the goods from storage (approx. 40% free space in the cold storage is required for the transfer of the goods)

- No interruption of the cold chain!

- Saving of renting a refrigerated container

- No additional personnel cost

- Little time required: a cold store of approx. 40 m2

- It can be cleaned in about 5 hours

- Use of a food safe cleaning concentrate, developed with the support of the Prof. Dr. Bremser, University of Paderborn