Cleaning bus cooler with JetBoy SP

JetBoy SP is the smaller brother of JetMaster. The use of JetBoy SP is almost completely sufficient for cleaning the fin heat exchangers of air conditioning systems. The advantage of the JetBoy SP over the larger JetMaster is the much lower compressed air consumption starting at approx. 1.50 m³/min. This already makes it possible to use compressors with outputs of 10–14Kw.

JetBoy SP, with a compressed air consumption of 1.50–2.25 m³ /min. from 5 bar pressure, offers new possibilities for cleaning the heat transfer apparatus of air conditioners and coolers. JetBoy SP works without electricity with min. 0.20 l water per minute. Due to the cavitation effect of the nozzle jet, cleaning of heat exchangers without any use of chemicals is usually sufficient. However, for special problems and the cleaning of other surfaces, the JetBoy SP can also be used with a cleaning agent or even disinfectant. Cleaning agents approved for the JetBoy SP are supplied. The sensitive fins of the heat exchangers are not damaged by the gentle jet cleaning with JetBoy SP.

Bus radiators usually have somewhat more sensitive structures. Here, the JetBoy SP can fully exploit its advantages.

To the Video JetBoy SP removes even heavy oil contamination from a bus intercooler

To the Video JetBoy SP effortlessly blasts through the package of oil and water cooler

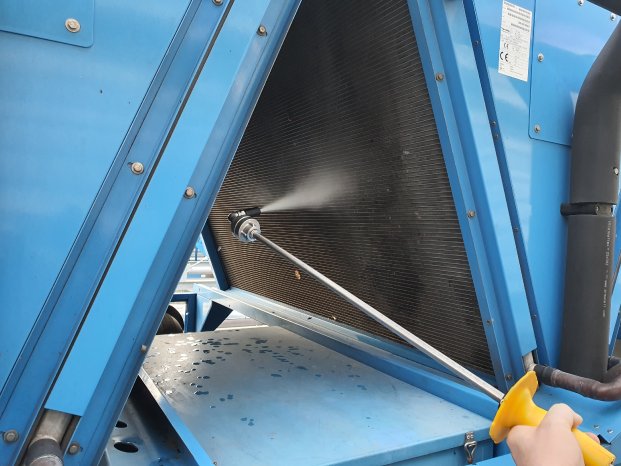

Cleaning the V-coolers of a data center with JetBoy

Our customer uses the JetBoy for cleaning the sensitive fins of the V-coolers of the manufacturer ENGIE. Although the total surface area is in the three-digit square meter range, the JetBoy's performance is sufficient for effective cleaning here. Quick-change lances/blast nozzles allow easy and fast cleaning of the entire area. The air compressor used with a nominal capacity of 580 l/7.5 bar is fully sufficient to supply the JetBoy.

To the Video JetBoy - Cleaning of V-Cooler

JetBoy cleans finned heat exchangers of any design