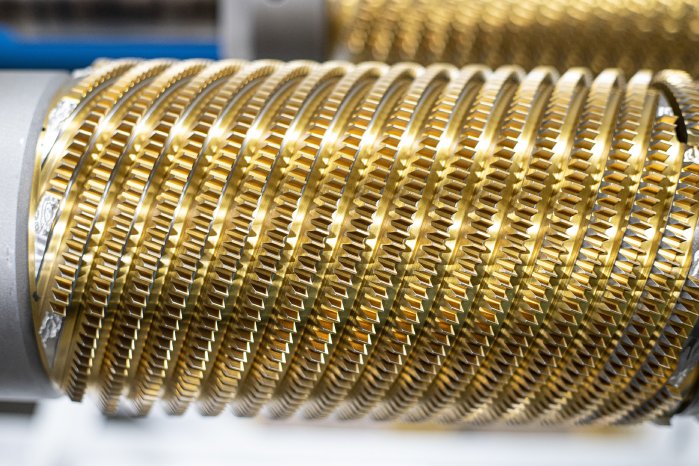

Federal Broach’s journey has been one of remarkable growth, fueled by an unwavering commitment to excellence in serving key industries like automotive, large truck manufacturing, aerospace, agriculture, and defense. Spanning an impressive 96,000 square feet (about 8900 m2), its cutting-edge manufacturing facility specializes in producing broach machines, a variety of broach tools, and the sharpening and recoating of gear-cutting tools. Notably, the company boasts its own coating facility, a rare feature among gear-cutting tool suppliers, highlighting their dedication to offering comprehensive solutions to customers.

To meet the escalating demand for gear-cutting tool services, Federal Broach recently augmented its capabilities by integrating a second coating system. This strategic enhancement positions the company to efficiently handle increased business volumes, providing crucial support to gear manufacturers across the United States.

A pivotal element in Federal Broach’s enduring success and expansion has been its strategic collaboration with NUM, a global leader in CNC control solutions. This partnership, which commenced in 1999 when Federal Broach embarked on upgrading its Brown & Sharpe spline grinder, has proven instrumental in modernizing its operations. Ken Kernen, President of Federal Broach, recalls the early days, highlighting NUM’s willingness to engage in a custom, one-off project. This collaboration laid the foundation for Federal Broach’s standardized use of NUM for many of its broach production machines, a testament to NUM’s commitment to innovation and customer-centric solutions. Ken Kernen recalls: “NUM was willing to work with us. We had a custom, one-off project. None of the other approached CNC control suppliers were interested in a one-off custom job. Now we have standardized on using NUM for all our broach machine products.”

Reflecting on the partnership, Kernen emphasizes the invaluable support provided by NUM’s customer service team, which surpassed expectations during the initial project. Federal Broach has consistently turned to NUM for various projects, leveraging NUM’s flexible controls and drive systems, allowing them to tailor machine interfaces and functions for specific operations. This collaborative approach has significantly enhanced efficiency, maintained impeccable quality standards, and prolonged the lifespan of Federal Broach’s high-value machines.

In 2023, Federal Broach and NUM joined forces once again to introduce the 10T economical broach machine, marking a natural progression from their successful collaboration in broach tool production. Seeking a partner with a global presence, exceptional support infrastructure, and a diverse product range to meet machine requirements across all lines, NIDEC chose NUM for this endeavor.

The broach machine process entails the precise interaction between the workpiece and the broach, a multi-toothed cutting tool with progressively larger teeth or cutting edges. The broach is gradually fed into the workpiece at a controlled rate, while its teeth progressively remove material to form the desired shape or feature. Modern broaching machines, including the 10T economical broach machine, have transitioned from hydraulic systems to electric servo drives for enhanced precision and control.

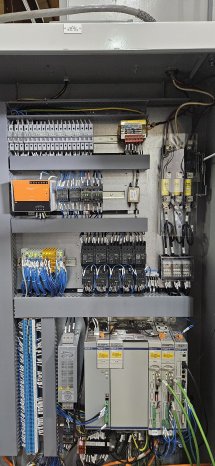

The NUM Flexium+ CNC and MDLUX Servo drive system emerged as the ideal solution, providing a unified hardware and software platform that seamlessly integrates with base non-helical models and extends to NIDEC’s more complex dual ram and helical machines. This approach empowers Original Equipment Manufacturers (OEMs) to capitalize on application expertise, optimizing control engineering efficiency to deliver competitive machines. NUM’s MDLUX motor/drive kits for the axes (known as the Loader, Handling, and Ram) epitomize versatility in motion control, delivering the precision required and providing the power necessary for the broaching process.

The key advantages of the NUM CNC and drive system encompass precision, flexibility, energy efficiency, minimal maintenance requirements, and enhanced control over the machining process. These attributes collectively contribute to improved productivity, operational efficiency, and cost-effectiveness for Federal Broach and its customers.

This state-of-the-art machine from Federal Broach, powered by NUM, demonstrates the seamless integration of cutting-edge technology and precision engineering. The NUM Flexium+ 6 serves as the cornerstone, providing a robust platform for streamlined operations. Notable features such as the Early Block Change function to begin executing movement of the next block before the current block has ended, a standardized PLC Control system, flexible EtherCAT IO and safety modules, and an enhanced operator experience facilitated by a 12 inch FS122 display running custom made visualization screens all contribute to Federal Broach’s commitment to providing machines that are efficient, high quality, and high safety.

The successful collaboration between Federal Broach and NUM embodies the strength of innovation, strategic alliances, and a mutual dedication to enhancing manufacturing capabilities. The extensive utilization of NUM components in the 10T broaching machine reflects the depth and breadth of this partnership, reaffirming Federal Broach’s dedication to innovation and excellence in manufacturing. While Federal Broach leads the way in pioneering precision and innovation within broach tool production, NUM continues to be a reliable partner in promoting efficiency, quality, and technological advancement.