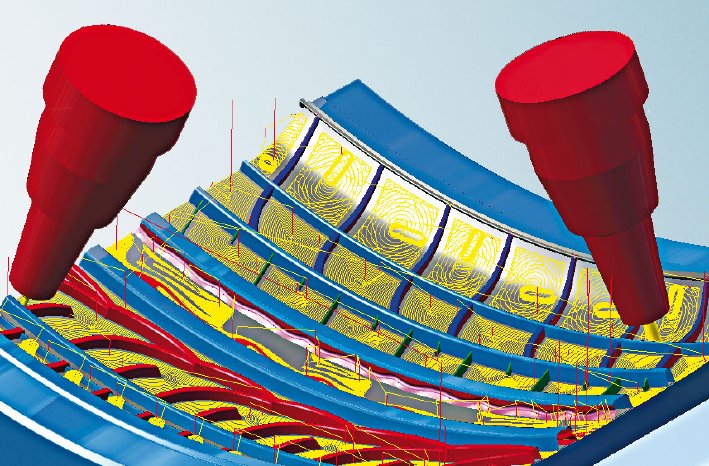

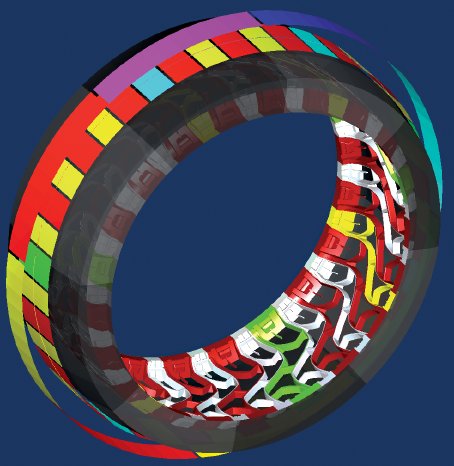

Characteristic geometries can be defined as features and standard machining sequences saved to a macro database. The milling strategies, for example, for knifecuts and stone ejectors as well as other details, can thus be programmed faster as recurring machining sequences. The recurring arrangement of identical tyre sections is often described by way of a 'tyre clock'. hyperMILL® uses this information for efficient programming. The user assigns the numbers of the individual pitches to the machining programs for this purpose. Each pitch is programmed only once. The generated program is copied to the corresponding tyre mould segments on the basis of the pitch number, and the CAM software generates the complete segments automatically. Toolpaths that go beyond the segment limit will be adjusted by hyperMILL® automatically.

No unnecessary movements

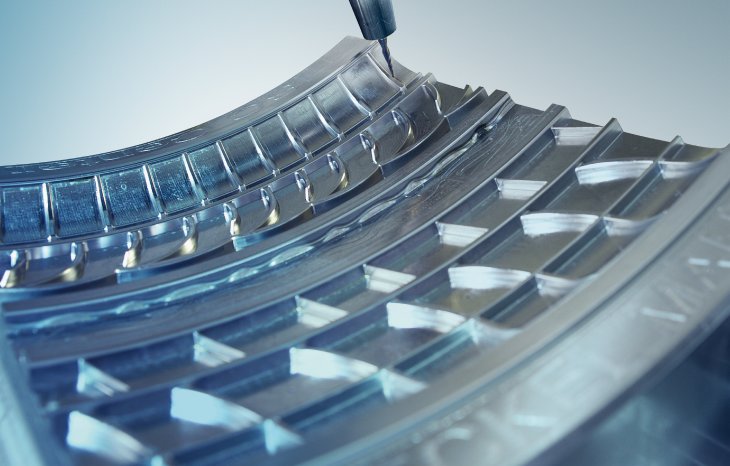

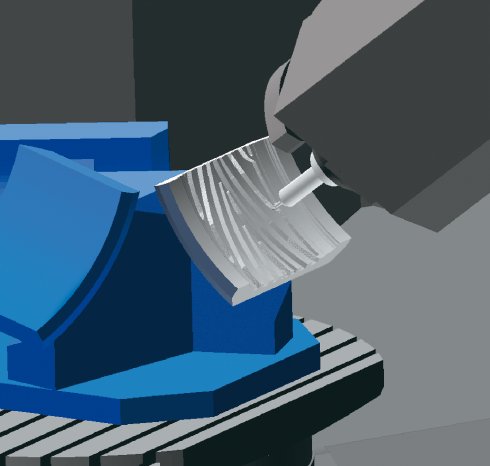

The machining of the complex geometries in tread patterns is implemented by the automation technology in hyperMILL® in such a way that all tool movements are calculated as efficiently as possible - but in a careful manner for the tool and machine. hyperMILL® automatically calculates collision-free tool positions, which means machining operations with various tool orientations can be generated quickly and simply in a single operation. In particular, the automatic tool positioning substantially reduces the amount of time that is required to program the intricate structures of tyre moulds. The cutter also moves closer to the object thanks to the simultaneous, collision-tested movement. Redundant movements are thus avoided.

Optimal material removal with as few steps as possible

The strong points of hyperMILL® are the machining strategies that the CAM software also fully exploits in tyre moulding. This starts with roughing, in which the hyperMAXX® module supports the programming of effective machining paths. Of special interest in this context of tread patterns is also the machining cycle of the 5axis rest machining. This cycle recognises all rest material areas - also in undercuts - and machines these in a single collision-free operation. Since it produces particularly smooth movements, the sharp edges of the tyre moulds can be machined precisely with narrow tools without having to be reworked.