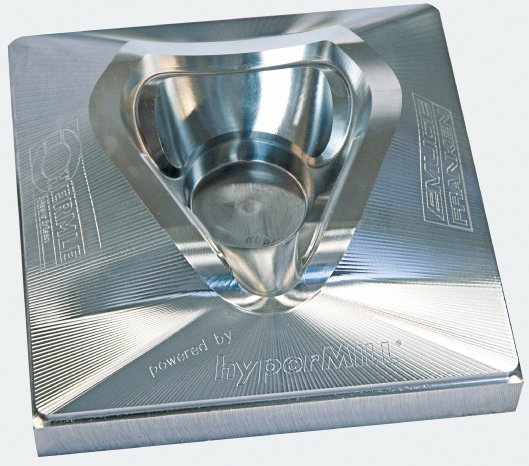

One of the highlights in milling the mold for a respirator mask was the tangential milling technique that utilized a barrel cutter. This is one of the strategies that will be available to users of hyperMILL® 2013. It is an example of how tool manufacturers and CAM developers are working hand-in-hand to make cutting machining even more efficient. The barrel cutter from EMUGE FRANKEN that is required for this function is also a new design. The machining strategy uses the streamlined shape of the milling tool in combination with its fluted segment of large radius cutting edge. The radius of the milling tool allows 5axis swarf cutting with greater step-over distances to efficiently create free-form surfaces.

Roughing and rest material removal

In between live presentations, interested trade fair visitors got an insight into the many functions of hyperMILL® before machining of the mold started up again. This allowed visitors to see both the hyperMAXX® high-performance roughing strategy as well as 5axis rest machining in action. This strategy searches each of the areas to determine which can be milled in a single operation using a fixed tool inclination. The multiple segment areas are linked by a 5axis simultaneous machining movement. This combined solution with indexing and simultaneous motion optimizes both programming time and cutting times.