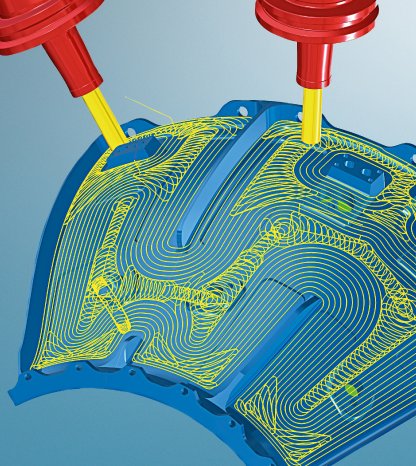

There are high demands on manufacturing performance in the aerospace sector. The focus is on topics such as weight reduction, reducing costs and increasing quality, reducing production times, machining new materials and materials that are difficult to machine, and on the use of certifiable processes. As a pioneer in 5-axis technology, OPEN MIND offers intelligent solutions for these challenges with its hyperMILL® CAM/CAD system. hyperMAXX® provides users with a high-efficiency, high-performance cutting strategy that achieves much higher material removal rates and also protects tools and machinery at the same time. The roughing module is fully integrated into hyperMILL® and combines optimal milling paths, maximum material removal and the shortest possible machining times. The strategy for extremely rapid material removal, even with materials that are difficult to cut, is available for 2D, 3D and 5-axis milling tasks.

Another strategy for mastering the typical challenges in the aerospace industry is 5-axis shape offset roughing and finishing. This function makes it possible to machine curved surfaces with a consistent allowance. The use of automation ensures that the milling paths always follows the base surface. This results in optimal surface quality with reduced programming effort.

Automated programming

One of the outstanding features of hyperMILL® is the numerous automation options, with which extremely efficient machining of complex workpieces is easy to implement. The user can also use these options for machining multi and single blades. Special hyperMILL® packages for impeller, blisk and turbine blade machining provide programmers with a wide range of capabilities.

Always on the safe side

A prerequisite for safe machining is reliable collision monitoring and avoidance, not just for 5-axis machining. hyperMILL® detects collisions and provides efficient solutions for avoiding collisions.

Continuous, flexible and process-reliable

Any workpiece can be programmed extremely easily and flexibly with hyperMILL®. All strategies for 2D, 3D, HSC, 5-axis machining and mill-turning are available in a single user interface. As far as the user is concerned, this means continuous processes and minimised machining times for maximum process safety, cost-effectiveness and quality.