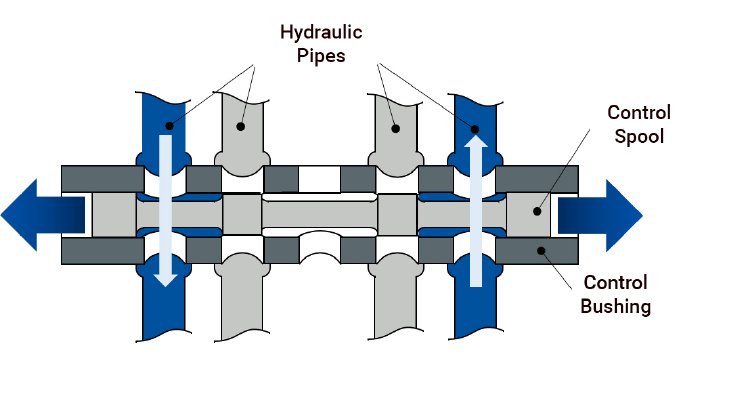

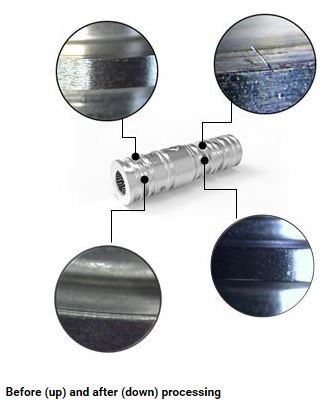

These servo valves usually feature bushings and spools alongside other components. Burr formation and high friction between the bushing and spool produce abrasion and wear, which in turn can cause the valve to fail. Sharp or unevenly rounded edges can also impair the valve's flow when it’s open. This makes it very hard to ensure that a replacement valve responds in exactly the same way as the old one. To guarantee safety and stability and ensure that installed servo valves function consistently, their critical points are subject to further processing after mechanical manufacture.

Precision deburring and smoothing of roughness peaks along with defined edge rounding on bushings and spools not only reduces friction in the valve but also increases its contact ratio. High-precision processing also enables the closest possible tolerances – a critical factor in system tightness. It also permits a higher switching or stroke frequency, significantly increasing control accuracy.

In current practice, these components are often post-processed by hand. But this has some serious downsides in terms of efficiency and process reliability.

The human factor plays a major role in manual processing: the results are literally in the hands of the person doing the work. Depending on the worker and indeed even the same worker on a different day, the component will either meet stringent requirements or end up in the reject bin. And let's not forget the cost factor. Diligent manual processing takes a lot of time: depending on component size, throughput can be limited to three or four per man-hour.

What’s more, the tools used for manual processes are sometimes liable to heavy wear, in which case every pass affects their qualities and therefore the end result.

OTEC stream finishing: reproducible post-processing that boosts process reliability and efficiency

Customers in the aerospace industry can take advantage of this optimisation potential by using the OTEC stream finishing process. Finishing servo valves with a consistent flow of media and strictly monitored parameters guarantees maximum process reliability and repeatability. And that means a much lower reject rate. OTEC systems can pay for themselves in as little as two to three months. The pulse finishing process used with our stream finishing machines reduces cycle time by up to 96% compared to manual processing. Our SF3/3 RLS machine with automatic workpiece loading system can process a component in 40 seconds-flat.

Stream finishing (SF) + Pulse finishing = Superb surface quality in minimal time Pulse finishing, OTEC’s stream finishing innovation, has remained the fastest mass finishing process on the market ever since it was launched in 2013, with average process times of 60 seconds.

Using very small grinding bodies compatible with the process, it produces precise, effective, ultra-consistent results even with complex workpieces.

OTEC stream finishing systems are cost-effective, process-oriented solutions that combine easy automation with maximum process reliability

About OTEC Präzisionsfinish GmbH

OTEC GmbH Präzisionsfinish provides precision technology for achieving perfect surfaces. OTEC machines are used for smoothing, precision edge-rounding, polishing and deburring a wide variety of workpieces, with the aim of improving surface quality. OTEC has a global presence supported by international business partners. OTEC’s comprehensive, market-leading technical expertise in developing the perfect interplay of machine and abrasive benefits a wide range of industries including tooling, medical devices, jewellery, and automotive and aerospace.Press contact

OTEC Präzisionsfinish GmbH | Heinrich-Hertz-Strasse 24 | 75334 Straubenhardt-Conweiler

Tel. + 49 (0) 70 82 - 49 11 20 | Fax + 49 (0) 70 82 - 49 11 29 | info@otec.de | www.otec.de