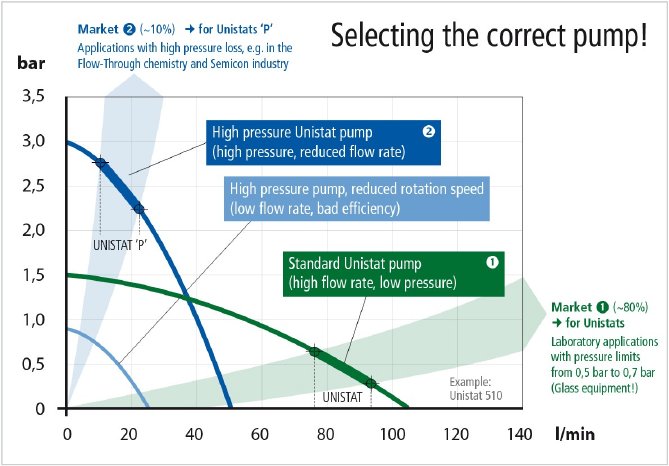

Significantly fewer applications have narrow cross sections by design and therefore high pressure drops. They therefore also allow (and require) higher pump pressures. Circulating pumps with a high discharge pressure are sensible in such cases - but in such cases only. This does not require controlling and reduction of the circulation pressure as these systems require the best possible circulation volume for an optimum heat transfer too. Typical applications are found in Flow-Through chemistry and in the Semicon industry.

Huber expanded the Unistat series for these applications with new models, which are equipped with particularly strong pumps. The new Unistats with the added 'P' (for pressure) have circulating pumps with high pressure.

The cooling capacity data of Unistats are always provided at full pump speed. Often, this is not the case for other brands. That's why cooling capacity data require closer inspection: The cooling machines must compensate more heat from the pump when the pump runs at full capacity. Between 200 and 900 watts less cooling capacity are available for the temperature control process if the cooling capacity data are not specified for the full pump capacity - and the end temperatures will no longer be achieved.

For more information, refer to www.huber-online.com or call us at +49 (0) 781 9603-0.