The hybrid machine combines five different processes in one machining center: Grinding, drilling and milling in just one clamping, deep grinding and optionally the additive method of laser deposition welding in the other. This does not only save machine costs but valuable changeover and retrofit times. Trade visitors can learn all about the millGrind BL10 multifunctional machining center and its small brother the millGrind BL5 at booth D46 (hall 11) and in a press conference (09/17/2019, 10:30 am, CC, Room 104).

The PSS Group is characterized by the many decades of experience in the development of cost-effective machining solutions for virtually any application of each of their individually established product brands. This company group was started by Lapmaster and Peter Wolters, which merged in 2014 to form the Lapmaster Wolters Group. Then the brands Elb-Schliff and aba Grinding joined the group in early 2017. In 2018, REFORM Grinding Technology joined the group. At the beginning of this year, Kehren and the wafer business of Meyer Burger with equipment for photovoltaic and special materials, among others, for the semiconductor and sapphire glass industry were added under the umbrella of PSS. “The PSS Group now has more than 1,000 employees worldwide at ten production sites on three continents, providing technical solutions for a wide range of applications,” says Matthias Mantel, CEO of the PSS Group in Germany. “At EMO 2019 in Hanover, we would now like to give the interested trade audience an insight into our skills as a solution provider.”

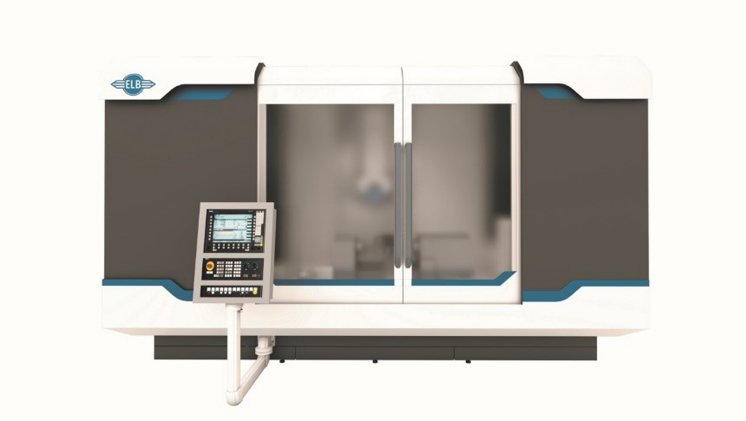

We are going to present the millGrind by Elb-Schliff as a highlight at the booth of the PSS Group. The manufacturers designed the millGrind mainly for the aerospace and supply industry, where there is a trend towards complete machining, especially for turbine components. Blades, rotor and turbine blades often require milling or drilling in addition to primary machining by grinding. “These types of parts can fully benefit from the advantages of the millGrind concept,” says CEO Matthias Mantel.

With 2- or 3-axis Indexing Head

Thanks to the high axis speeds, non-productive times are reduced to a minimum. The machine is equipped with a powerful spindle that performs milling and drilling operations up to 10,000 rpm (millGrind BL10). The overhead dresser was specially developed for highly productive deep grinding and, according to Elb-Schliff, offers a genuine competitive advantage over other machining centers.

An additional dressing device is installed on the work table to create flexible grinding wheel profiles. This is mainly intended for interpolating the dressing

with diamond section rollers.

Modularly Expandable Tool Changer Magazine

The tool changer enables the simultaneous change of dressing roller and grinding wheel – this saves set-up time. The magazine holds up to 60 tools, including grinding wheels, dressing rolls, measuring probes, and milling and drilling tools. In addition, the tool changer magazine is also modularly expandable.

Included in the millGrind: Component Measurement

With the new millGrind, Elb-Schliff meets the trend of in-process measurement. The integrated measuring probe is operated via a flexible software package. On the one hand, clamped unmachined parts can be measured to compensate for positional and clamping errors automatically. On the other hand, finished parts can also be measured.

Optional Additive Laser Deposition Welding

As an available option, a laser head can be easily integrated into the machine via a tool change to realize the laser hardening, marking, and additive material welding functions. Laser deposition welding is a fast high-precision method for metal welding and therefore particularly suitable for precision components in aircraft construction. Grinding is particularly economical when machining difficult materials such as nickel and superalloys in aircraft construction. Deposition welding can also be used for the repair of blades. It can then be ground to size in a second machining step without re-clamping.

Operating Errors Excluded

The clamping technology is of particular importance in automated complete machining, and in particular with turbine blades. Exact positioning of the workpieces in the device is not possible with turbine blades due to the large film deviations of around ±0.1 mm at the clamping points. Before machining, it is therefore expedient to measure the position of the components in the device using a coordinate measuring machine within the cell. The measurement results are then converted into compensation data and assigned to the respective processing machine by the cell control on a component-specific basis. The 6-axis design of the processing machines thus makes it possible to compensate for the majority of clamping errors. “Within the cell, the components, devices, and tools can be traced clearly via RFID chips or data matrix codes – thus operating errors are practically impossible,” emphasizes Matthias Mantel.

Precision Surfacing Solutions at EMO in Hanover from September 16 to 21, 2019, Hall 11, Booth D46

Press Conference on September 17, 2019, 10:30 am to 11:30 am, Convention Center, Room 104