The ksl laboratory serves as the interface between complex customer inquiries and sophisticated robot and CNC-technologies. Based on many years of experience and expertise, customer-oriented solutions and concepts are developed at the ksl laboratory. Feasibility studies are carried out, prototypes and small batches are realized and special sewing heads for systems are designed and assembled. In addition, new developments are completed and various KSL-machines and components are tested and optimized.

The LABORATORY-concept significantly enhances the vital areas of pre and after sales. Experienced technicians and engineers from IT, sewing technology CNC- and control engineering form the backbone of this new section. Project machines for renowned customers from Europe, the US and Asia are designed at the LABORATORY and implemented in their production lines based on the customer requirements. Larger systems like the KL 504 or the KL 110 are assembled at the PFAFF INDUSTRIAL-facility in Kaiserslautern, since a bigger assembly area is available there.

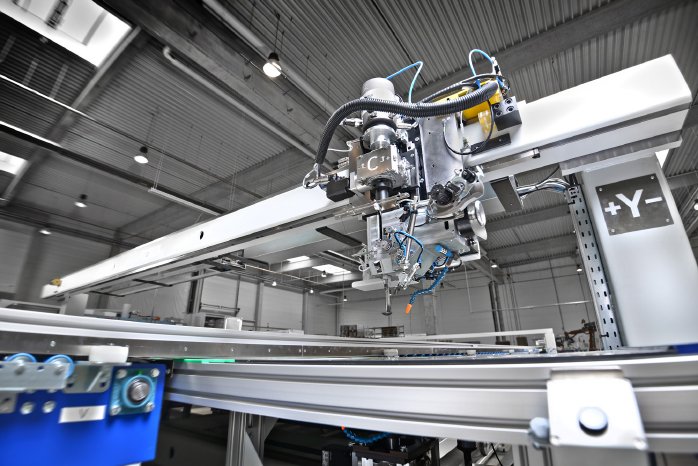

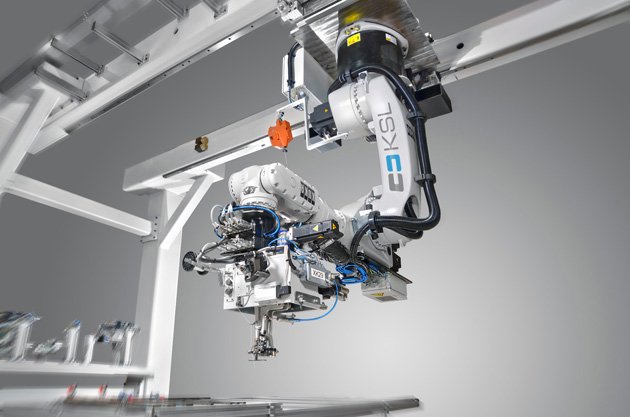

KL 504

The portal facility with suspended robot has a defined workspace of 8 m x 3.5 m x 1.5 m. The facility is equipped with the following functional heads:

- Blind stitch sewing head RS 512

- Double needle sewing head RS 530

- Tufting sewing head RS 522

- Ultrasonic cutting head

- Laser measuring head

Even complex geometries are workable owing to the portal design in combination with the use of robots. An ultrasonic cutting head, which can be automatically picked up and stored using a tool change system just like all other function heads, is used for cutting dry fibre material and prepreg material. A measuring head with laser scanning enables automatic position correction of components by means of a software tool for the measurement and calculation of shifts. Additionally with the portal system there is the option for simulation and offline programming on a separate workstation. Reachability and collisions are checked there. The thread tension for the blind stitch and double needle head and the thread consumption for the tufting head can also be monitored and documented on this station.

KL 110

The CNC sewing system works with a lock stitch for sewing carbon and glass fibre fabrics in the 2D area. The working range of the system is 8 m x 3.5 m. The machine is equipped with a rotary head in order to ensure optimum sewing quality in all seam directions. The sewing material is supported on this system across its whole surface and handled exceptionally carefully by means of a special belt system. To facilitate programming, a DXF converter is available which directly outputs a machine-readable program. The needle thread tension is monitored by a sensor system and exceeding the set limits leads to a stop of the system with an appropriate error message. There is also the possibility to record the yarn tension values.

In March the company will participate on the fair “JEC Composite Europe 2017" in Paris.