- Dry filtration (dust extraction, air-conditioning technology and ventilation technology)

- Liquid filtration

In the environmental, industrial or automotive sectors, for example, both fields of filtration are used in most cases, whereby the types and/or variety of filter types and materials have increased enormously over the last few decades. Nowadays, modern filter media consist of membranes or textile materials such as gauze, needle felt, fleeces and knitted fabrics (e.g. cotton, wool, viscose, acetate, polypropylene, polyethylene, polyvinyl chloride, polyamide, polyacrylonitrile, polyester, aramid and polytetrafluoroethylene).

When it comes to further processing these materials, PFAFF INDUSTRIAL has become an important partner in the sector, since pleated filters, tube filters, stocking filters, pocket filters, bag filters with and without support, etc., have to be manufactured and joining technology plays a key role in this regard.

In specific terms, these filter media are sewn together or welded using modern industrial machines. PFAFF Industriesysteme und Maschinen GmbH from Kaiserslautern is the only provider in the world to offer sewn and a variety of welding solutions for seaming technologies.

Without a doubt, PFAFF is the innovation leader in the sector, especially when it comes to welding textile materials. Several PFAFF product innovations have won industrial awards over the last few years. The welding procedure is predestined for use in the filtration field, where production techniques which either cause no or minimal damage to the surface are required (needle, thread, adhesive).

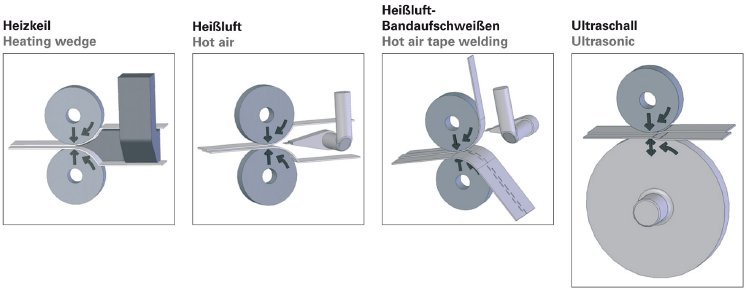

The following welding methods are used in PFAFF welding solutions

The experienced experts at PFAFF help their customers to decide which welding technique is suitable for the material in question. Under certain circumstances, the material needs to be tested in PFAFF's showroom and test centre in Kaiserslautern, which measures more than 1,000m2.

In dialogue with customers, reliable and efficient special machines have been planned and created over the last few years for pleated filter production, hot-air production systems for filter tube production or ultrasonic welding machines with up to five welding heads for producing filter plates or bags. Large and complex production systems can be custom-built at the premises of our affiliated company, KSL Keilmann Sondermaschinenbau GmbH.

PFAFF will be showcasing the following welding methods at the FILTECH trade fair in Cologne (24 - 26 February 2015).

PFAFF 8312 CS dual

Programmable ultrasonic welding machine as double wheel solution: simultaneous cutting, edge sealing and welding a second seam

IN ONE OPERATION

PFAFF 8320

Programmable hot-air welding machine with adjustable tube guide for the production of filter tubes

PFAFF 8317

Efficient single-head ultrasonic unit for cutting, edge sealing or welding of membrane filters or textile plates and panels

PFAFF 8323

Programmable cylinder-arm hot-air taping machine for continuous seam sealing with a tape, e.g. on filter tubes