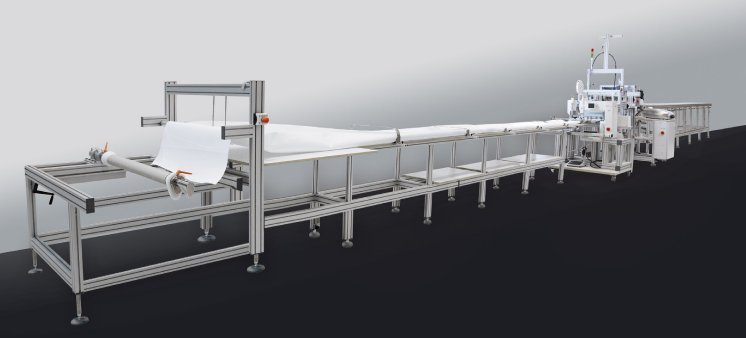

With the brands PFAFF INDUSTRIAL and KSL, the company has the necessary experience in process engineering, electrical engineering, automation technology and robotics to meet customer requirements for reliable, partly fully automatic solutions. A fully automatic production line for the manufacture of filter bags (with longitudinal seams) for an Asian customer is currently being manufactured in Kaiserslautern/Germany. At the heart of the system are the exchangeable hot-wedge welding and 3-thread chainstitch sewing units. Depending on the application, these can be implemented in the manufacturing process in just a few minutes. The raw material is unrolled, precisely formed and quickly and reliably fed to the sewing or welding unit. After joining, the 'tubes' are cut (filter length selectable via display) and automatically ejected. Optionally, the parts can be labelled using a printer. Depending on the material, the plant reaches a production speed of 10m/min.

At the FILTECH trade fair in Cologne (22 - 24/10/19) PFAFF INDUSTRIAL presents a new ultrasonic welding machine, a true world debut. In addition to regulating speed and welding power, the new PFAFF 8311 allows power to be measured and held constant during the welding process for the first time. Machine adjustment and handling is easier. The process becomes clearer, more reproducible and easier to understand. In short - the machine is raised to a new level. Another highlight of the machine is the trimming function. A cutting blade to the right of the weld seam can be switched on and off. These and other solutions will be presented at this year's FILTECH in Hall 11.1, No. E1.