Additive manufacturing: Flexibility for small quantities

Selective laser sintering (SLS) offers maximum flexibility and speed. Prototypes and low-volume production runs can be manufactured directly from CAD data without the need for complex mold making. This makes SLS the ideal choice for small quantities or particularly complex geometries. The advantages are obvious: fast production times, no initial investment and the ability to easily implement design changes.

Rapid tooling injection moulding: Efficiency and flexibility for prototypes and low-volume production

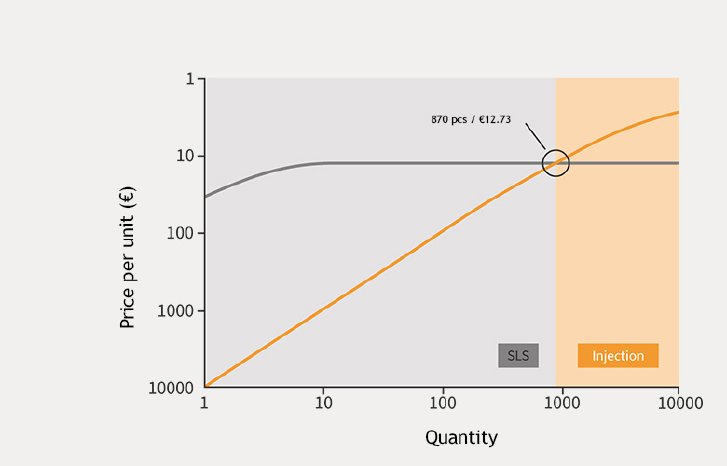

While additive manufacturing is ideal for small quantities and short development cycles, plastic injection moulding using rapid tooling with aluminium moulds has its strengths in other areas. The advantage is particularly clear for production volumes of around 100 to 1,000 parts, as tooling costs can be allocated efficiently to the units produced.

In contrast to traditional injection moulding, which is designed for high-volume production with steel moulds, priomold offers a specially optimized solution for prototypes and low-volume production. "With our Rapid Tooling process, we make injection moulding economically attractive even for smaller quantities," explains Moritz Zumdick, Managing Director of priomold GmbH. "By using aluminium moulds, we reduce initial costs and significantly shorten throughput times. This process combines the high quality and material versatility of injection moulding with a cost efficiency that is almost impossible to achieve with conventional processes for smaller quantities.

To make the decision between the two processes easier, priomold offers its customers comparative analyses. These show the number of units at which it makes sense to switch from SLS to injection moulding. For certain components - see graph - this point can be around 870 units, depending on the size and complexity of the part.

The ability to obtain additive manufacturing and rapid tooling injection moulding from a single source offers companies maximum flexibility. From the initial development phase to functional testing and low-volume production, customers can access the most economical solution from priomold at any time without having to change manufacturing partners.

Extended availability on the PROTIQ Marketplace

As an innovative addition, priomold GmbH is now also making both services available on the PROTIQ Marketplace. Customers can now use both flexible additive manufacturing (SLS) and precise plastic injection molding from priomold via the platform. This extension makes it possible to directly compare the respective strengths of the technologies and find the optimal manufacturing solution for specific projects - quickly, reliably and easily accessible.