Epoxy, silicone, and polyurethane polymers

RAMPF Group, Inc. utilizes expertise in epoxy, silicone, and polyurethane polymers for innovative sealing, casting, and thermal management solutions for battery housings, sensors, plugs, relays, and on-board chargers. The reactive polymer systems offer a wide range of mechanical, thermal, and chemical properties, meet the highest quality requirements, and ensure greater safety, control, cost-efficiency, and convenience.

RAMPF sealing systems based on polyurethane and silicone stand for efficient sealing, top quality, and exceptionally easy handling. The fast-curing, low-emission, heat-resistant systems protect battery covers, charging stations, and charging connectors against dust, dirt, moisture, chemical substances, and environmental influences.

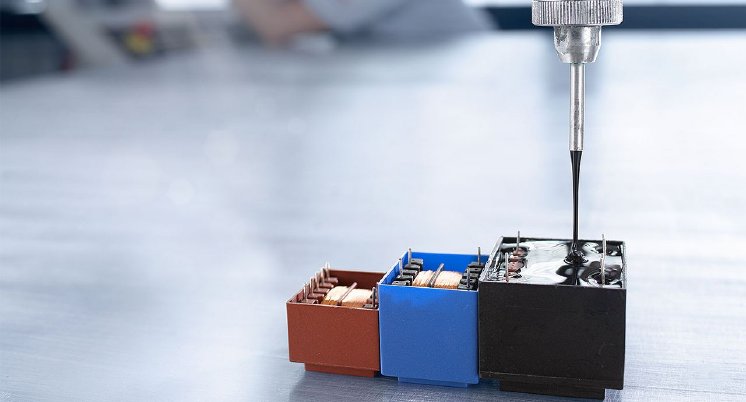

RAMPF casting systems based on polyurethane, epoxy, and silicone ensure optimum heat dissipation in batteries and power electronics, while providing long-term protection against chemical substances and environmental influences. This maximizes service life, reliability, and performance. Gap fillers and heat-conductive casting materials guarantee optimized heat management of electrical and electronic components.

Dispensing and automation systems

RAMPF Group, Inc. has comprehensive experience in high-performance production systems for the precision handling and application of polymers.

Mixing & dispensing technology – high-performance, low-maintenance systems for the ultra-precise dispensing of single-, dual-, and multi-component reactive resin systems; independent of fillers and viscosities.

Automation concepts – integrated parts transport and heat treatment, assembly and joining technology, logistic and quality assurance solutions, surface activation processes, testing and measuring technology.

Lance Ewert, Division Manager Reactive Polymer Technologies at RAMPF Group, Inc. – “Our material, application technology, and automation experts develop turnkey work cells that improve productivity, quality, cost, and consistency of polymer dispensing, handling, and curing. We also offer a highly dedicated customer service – from product development to market launch.”