Key facts

- RAMPF Group, Inc. offers contract manufacturing services for sealing, casting, and bonding reactive plastic systems.

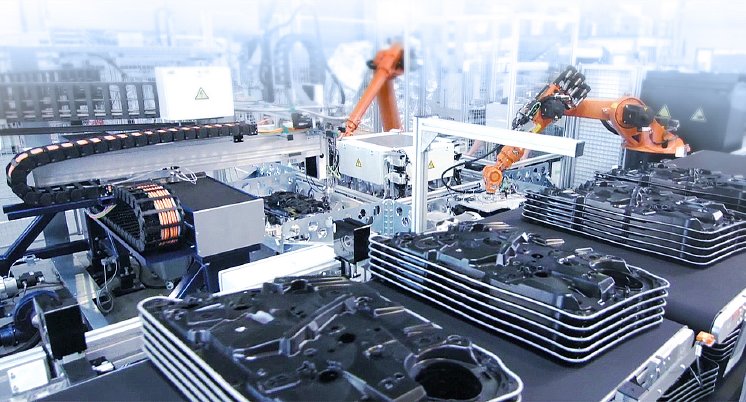

- The company develops and produces both the plastic systems and the respective automated mixing and dispensing technology; this guarantees a holistic service offering that is precisely tailored to the needs of the customer.

- RAMPF is the preferred partner in a number of industries, including automotive, electronics, energy technology, household appliance, lighting, and medical technology.

- Reactive resin systems – Polyurethane (RAKU® PUR), epoxy (RAKU® POX), and silicone-based (RAKU® SIL) systems, including sealing systems, electro casting resins, and adhesives.

- Automated production systems – Mixing and dispensing technology for sealing, casting, and bonding reactive resin systems.

RAMPF provides custom-formed-in-place gaskets (FIPG) and foam gaskets (FIPFG) using speed-robotic CNC dispensing. These gaskets expand and bond quickly on the component, ensuring reduced cycle times and efficient processing. The company also offers high-performance seals that exhibit exceptional chemical resistance and are designed to withstand high pressures and temperatures.

Casting

RAMPF processes reactive, thermally, and electrically conductive polymers with its premium mixing and dispensing systems, ensuring precise and fast handling of highly filled materials. The resulting parts are protected from contact, moisture, and damage, ensuring the longevity and high performance of electronic assemblies.

Bonding

RAMPF utilizes multi-component adhesives for the precision joining of components. Pre-treatment processes enhance adhesion, and high-precision joining can be conducted manually or fully automated. In-tegrated curing-on-demand systems accelerate curing, and vacuum joining ensures air-bubble-free applications for products like displays (optical bonding).

Visit RAMPF at AME 2024, Grand Rapids, MI, on August 8 and 9 – Booth 816!