Whether it is telecommunications, IT, the automotive industry, electronics or the entertainment industry - increasing numbers of components in these and many other sectors are produced from plastics. This is due to properties such as low weight, easy processability, virtually unlimited design freedom and comparatively low production costs. Parts such as 3D-MIDS, mobile phone housings, laptop housings, RFID transponders and flex boards frequently require metallization or coating for their function. The plasmadust technology offered by Reinhausen Plasma GmbH is the first process in the world to enable the deposition of metallic layers (e.g. printed conductors or EMC shielding) and coatings as a barrier layer, for instance, to improve sliding characteristics or abrasion resistance, directly onto the synthetic material using a cold-active plasma source.

Dry and Environmentally Compatible

Compared to other metallization and coating technologies on the market, the inline-capable plasmadust technology is impressive due to a significant reduction in the number of process steps necessary, simplified process control, low space requirements and optimization of both time and costs. This means, for example, that it is possible to dispense with galvanic processes or laser work steps for surface structuring. The dry process also scores from an environmental point of view because the metallization/coating is carried out without using any environmentally damaging solvents, surface activation, cleaning and drying processes, i.e. it is free of volatile organic compounds, and it is also energy efficient.

Material-friendly metallization/surface coating using a cold-active atmospheric pressure plasma generator

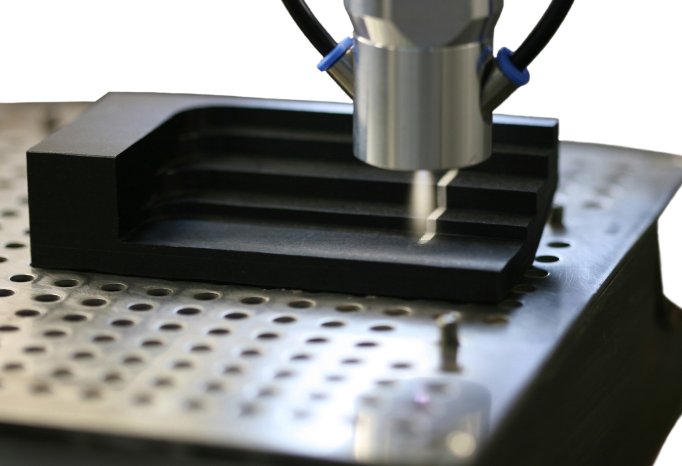

The plasmabrush PB2 developed by the company from Regensburg is used for metallization or coating and works under atmospheric pressure. In this system, the plasma gas is generated according to the inverter principle with a highly effective, pulsed arcing gas discharge. This creates a cold, non-thermal plasma with a temperature, depending on the nozzle, of between 120 and 250 °C under ambient conditions. This is significantly below conventional "cold" atmospheric pressure plasmas and ensures gentle treatment of the substrate.

The coating powder, such as copper, gold, tin and metal alloys, as well as mixed systems, such as boron nitride/Teflon, with a grain size diameter of 100 nm to 20 µm is fed continuously to the plasma. At the same time, specially developed atomizer/conveyor technology guarantees that the powder is free from agglomerates. Combined with an adjustable, even flow of particles, this ensures homogeneous and reproducible layers between 1 and 1,000 µm thick. The process speed is up to 150 metres per minute.

Activate and metallize in a single process step

Surface activation is usually necessary to improve the adhesion of metallic layers on plastics. An atmospheric pressure plasma is frequently used for this purpose. Using the plasmadust process, it is easy to integrate this separate treatment step into the metallization/coating process. The system's controller can be programmed so that first of all the surface is activated by the plasma jet and then powder is fed in to coat it.

Thanks to simple process control, shortening of the process chains and low space requirements, the plasmadust process offers enormous potential for rationalization when metallizing/coating synthetics. It also enables producers of synthetic components and companies that have previously had metallization/coating carried out externally to integrate added value creation in their production process.

plasmadust® is a registered trade mark of Reinhausen Plasma GmbH. The innovative direct metallization/coating process will be featured at K 2010 in Hall 11, Stand F 47.