Manufacturers are moving away from stand-alone power distribution enclosures for individual control units. Instead, they are looking to create an overarching system within a single enclosure, serving multiple controllers – each one assigned to a specific machine. The new Rittal RiLine Compact, designed for control units that require a maximum current of 125 A, addresses this need. Despite its size, the busbar system distributes power effectively and reliably, in compliance with all applicable standards. The innovative technology is ideal for small switchgear and controllers, and for direct integration into plant and equipment.

RiLine Compact marks Rittal’s entry into a new market segment for low-current power distribution. Currently, most systems designed for up to 125 A feature comb busbars or conventional wiring. However, this type of wiring devours time and effort, and can result in numerous individual connections – and a confusing configuration. Moreover, the drawback of comb busbars is that they vary by manufacturer and design type, and are not standardised and modular. And busbar systems are rare below 125 A, meaning many have a highly customised configuration, making assembly and installation complex and time-consuming.

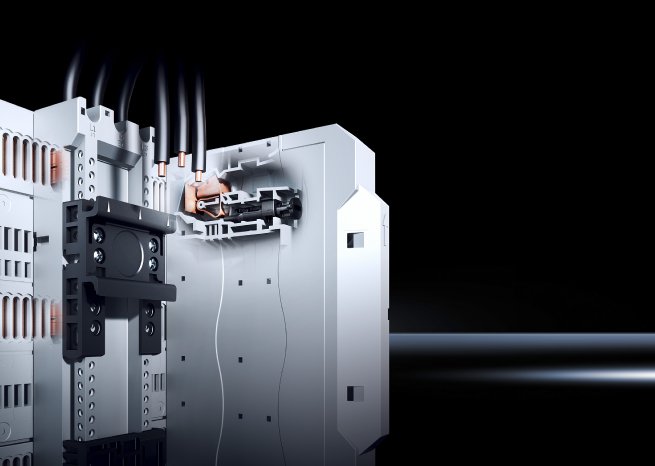

All-round contact hazard protection

RiLine Compact comprises a board with busbars entirely enclosed in covers that safeguard against unintentional contact. A connection can be easily established anywhere along the length of a busbar via a series of access apertures (called the pitch pattern) in the board. Switchgear and control units can be simply “plugged in” using a variety of adaptors. In addition, a adapter for connection to round conductors is available, as well as a variety of functional modules for motor and power control.

One of RiLine Compact’s primary strengths is that it can be rapidly configured, assembled and installed. The main board and diverse components can be securely mounted without the need for tools. Because the entire system is shielded by covers, users are protected against live parts. This enhances safety for operators and for the system as a whole. Furthermore, it saves time and cuts costs.