Numerous steps are needed to wire control or switchgear units; the wire must be cut to length, stripped, crimped, labelled and finally, the finished cable must be routed and connected. Wiring accounts for roughly 50 percent of the total work required in creating an enclosure, the lion’s share of the operation in other words. Thus, a great room for improving efficiency, which can be achieved with automated processes.

As many as 36 different wires

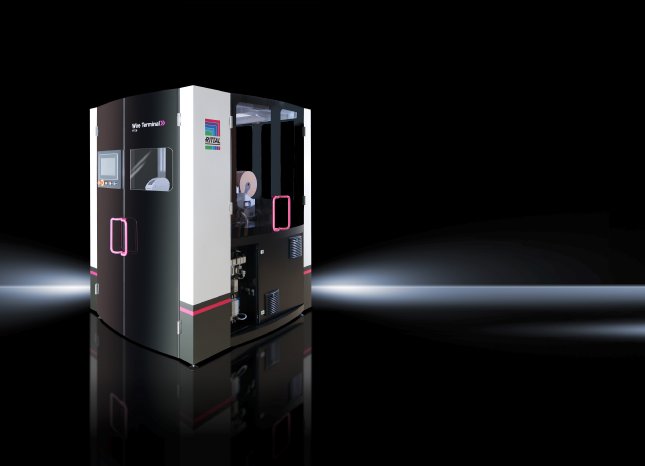

The new Wire Terminal WT, a compact and fully automatic wire assembly machine, available in WT24 and WT36 variants, helps make wiring more economical and efficient. As many as 24 or 36 different wires can be produced fully automatically in cross sections ranging from 0.5 mm² to 2.5 mm², without any retrofitting. The appropriate wire bearings have to be selected, depending on the number of wires. Cutting to the required length, wire stripping and crimping operations are carried out without an operator having to intervene. The printing system (optional) can print the wires black or white. Wires processed in this way are optimally transferred to the downstream process steps by the controlled classification system, which consists of a 13-fold storage system with wire rail magazines that can accommodate up to 1,300 wires.

The Wire Terminal can be equipped with a ‘lift’ option that enables a quick changeover to a variety of different automatic crimping machines if different crimping machines are used for dissimilar cross-sections. The standard version incorporates the RC-I insulation stripping and crimping machine. This enables five different wire cross-sections from 0.5 mm² to 2.5 mm² to be processed without having to change the wire end ferrules.

Simple and seamless data flow

Consistent data management is an important cornerstone for the maximum efficiency of automated workshop processes. The new Wire Terminal WT possesses the right interfaces for this. The data from construction planning with EPLAN Pro Panel can therefore be used seamlessly for wiring pre-assembly. Alternatively, the data can be directly entered into the machine by hand. The pre-assembled wires, which the Wire Terminal stores in the classification system, are available for wiring. This way, the wires are sorted according to need so that work can be optimally performed with the EPLAN “smart wiring” tool.

Faster and better wire processing

The Wire Terminal WT can speed up wire processing in control and switchgear engineering eight-fold. At the same time, fully automatic manufacturing guarantees a consistently high quality. An investment in automated wire processing of this nature also makes sense for small and medium-sized control and switchgear engineers. The investment can quickly begin paying off with as few as 300 enclosures per year.