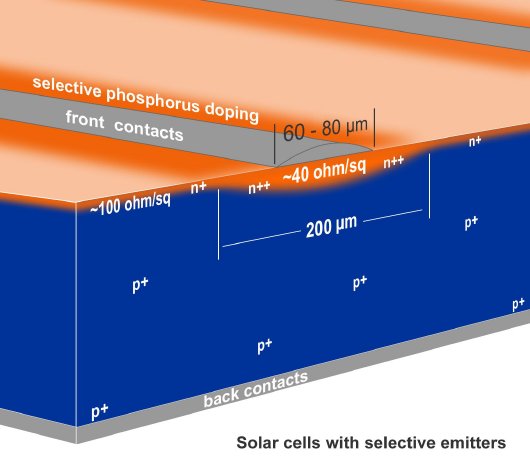

Selective emitters promise efficiency gains of about 0.3 - 0.5% compared to standard homogeneous emitters. In the past, there has always been a trade-off between the desired heavy doping of the n-type silicon layer underneath the metallized contact regions and light doping between the contact fingers. Heavy doping achieves low contact resistance and good lateral conductivity whereas, light doping is necessary for limited recombination and good response to blue light. Laser doping uses the phosphosilicate glass (PSG) layer, already grown on top of the emitter during conventional dopant diffusion, as doping source - no additional cost driving dopants are required. With an optimized pulse length regime, the laser process is diffusing the additional Phosphor atoms into the silicon emitter without causing heat affected damage to the bulk silicon. In fact, the texturized silicon surface doesn't even melt in the process.

Originally the doping width of 300micron was designed for a metallized finger width of around 100micron leaving enough room for printer to laser alignment. With advances in process accuracies and fine line printing down to 60 - 80 micron being introduced into industrial mass production, ROFIN is responding with a product upgrade for selective emitter processing. Two new versions with the unique, patent pending rectangular spot design are being offered (as pictured below):

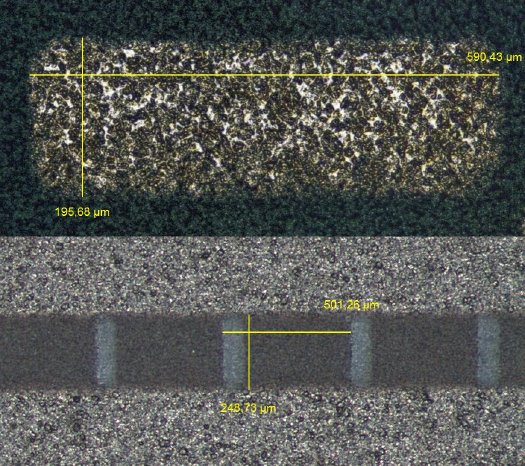

- 250 x 500micron flat top spot area

- 200 x 600micron flat top spot area with Powerline L 80 SHG

A laser doping line of 200micron under the fingers compared to a 300micron width enlarges the total area with reduced recombination and better blue light response by 1250 mm² (or 5%) and pushes the cell efficiency further up. The calculation is based on an 80 finger 156 mm cell design. The upgrades are available for new laser systems as well as lasers already installed. The 200 micron line width comes with a new laser resonator version and enhanced beam quality, the Powerline L 80 SHG.

Laser Systems for high throughput cell processing ROFIN and CENTROTHERM have successfully introduced fully integrated laser manufacturing systems for selective emitter and rear side passivation to European and Asian high volume c-Si cell manufacturers over the last 2 years. Detailed results of cell efficiencies in mass production have been presented at various technical conferences.

ROFIN is now broadening the product range for its "Dual Line c-Si" (TM) machine to other applications as laser fired contact, front side scribing and metal wrap through cell (MWT) drilling. The core of the machine is a high precision granite base to support the laser optics and rapid wafer handling units. Features are a standardized HMI software and a powerful PLC system allowing a throughput range of 1800 - 3600 wafers per hour. The machine can be equipped with a wide range of options:

- Quality control system and sensors

- MES host interface

- Inline, cassette or coin stack handling for all common standards and degrees of automation

COO, Thomas Merk: "The Photovoltaic Energy Industry is one of our strategic key markets. The current main task of our PV customers is to increase the efficiency of their solar cells to levels of higher than 20 %. Rofin has focused its product portfolio exactly according to these requirements. Dedicated production and lab solutions for selective emitter, backside opening, MWT, etc. applications have been launched successfully to the market. With local offices in all relevant regions and with high competitive solutions ROFIN is best positioned to support our PV customers."