As part of KraussMaffei's "Circular Economy" project, PP buckets are initially produced on a GX 1100 injection molding machine and shredded externally. Afterwards the milled material will be talcum-reinforced, colored and re-granulated on a ZE 28 BluePower twin-screw extruder.

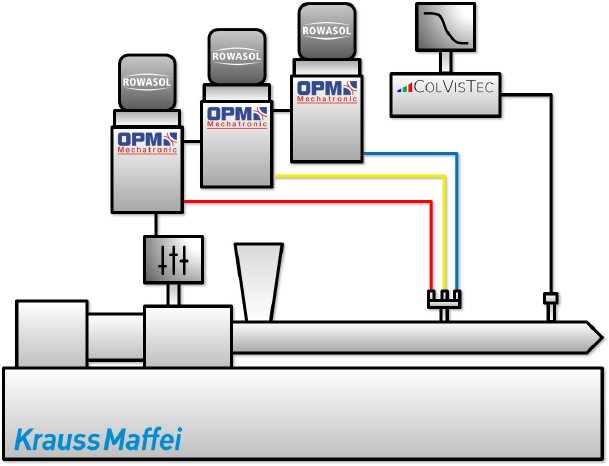

The color is added by an eccentric-screw dosing system to inject three liquid colors directly and simultaneously into the plastic melt. The colorant is homogeneously mixed with the plastic directly by the compounding extruder's specially configured twin screw. The master and the two slave modules are controlled and the formulation managed by KraussMaffei's central extruder control system.

The liquid colors are supplied in re-usable ROWASOL COLOR CUBE containers for clean handling.

This innovative principle makes it possible to adjust the color whilst the process is running and change to production of a completely different color in a matter of seconds. The three colors on exhibition red, yellow and blue cover a wide spectrum of colors according to the RGB principle.

To complete the process, an inline color measurement directly in the polymer melt with an UV-VIS spectrophotometer from ColVisTec AG, Berlin, follows shortly after the color addition near the extrusion die. This enables real-time monitoring of the color change and continuous quality assurance.

After the compounding the re-granulate is processed on a PX 320 injection molding machine from KraussMaffei into an A-pillar support for automotive applications. This entire process illustrates in a tangible way how the "Circular Economy" can be perfected using modern methods.