New or revived trends and styles are constantly emerging both in the packaging and in the design of containers for the cosmetics industry. A metallic look and decorative design using lasers have been very popular for some time. To meet this demand, ROWA Masterbatch includes optimized raw materials in its portfolio. The specialist for polymer-specific color, additive and combination masterbatches provides its customers with color masterbatches that ensure metallic looks and laser possibilities without any loss of quality.

Laser marking has become a popular method of identification because of its many advantages: laser markings are more stable and more permanent than pad printing, for example. They can be used on a wide variety of surface structures and shapes, even curved designs, and they are abrasion and weather resistant, lightfast and resistant to chemicals. A further plus point of laser marking is the flexibility that templates can be created quickly and various layouts are possible.

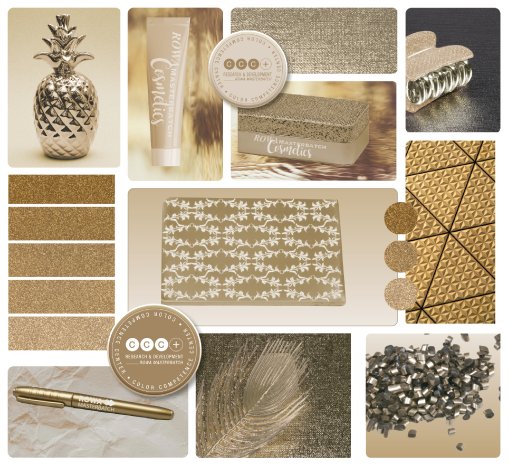

In addition to marking, using lasers for decorative purposes is currently in high demand in many industries, especially for packaging and in the cosmetics sector, where metallic looks are very fashionable. The laser treatment of metallic-looking surfaces used to be associated with a loss of quality, as the laser additives that were required made the metallic look less shiny - at least until now! ROWA Masterbatch has developed different color masterbatches that replicate a metallic surface extremely well. They can now be lasered without loss of quality, maintaining the rich, brilliant color tone with a shiny metallic look - not only for light-dark color changes, but also for bright colors with a metallic appearance.