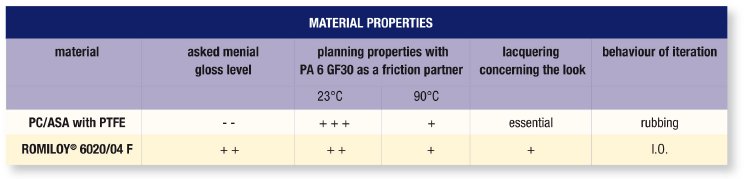

Nevertheless, particular attention must be paid to the friction pairs. Compounds have been specially developed for plastic components made of ABS, PC+ABS, PC+ASA and PA-blends that provide tribological advantages when paired against PA com-pounds with mineral or glass reinforcement. These compounds have another advantage over material solutions containing PTFE that have a lower surface quality and which undergo greater wear in continuous operation tests: they are characterised by very good abrasion resistance and do not require an additional coating.

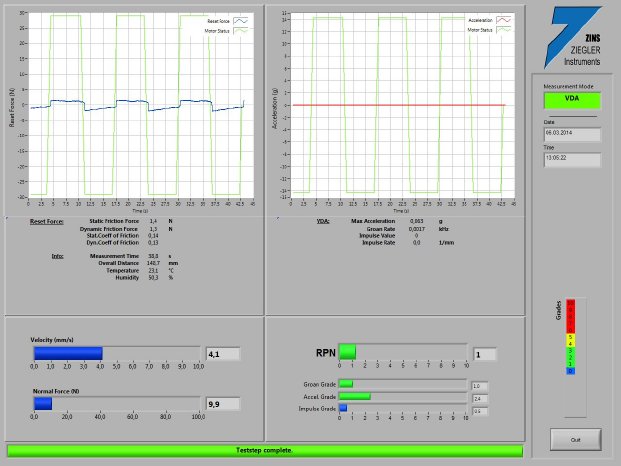

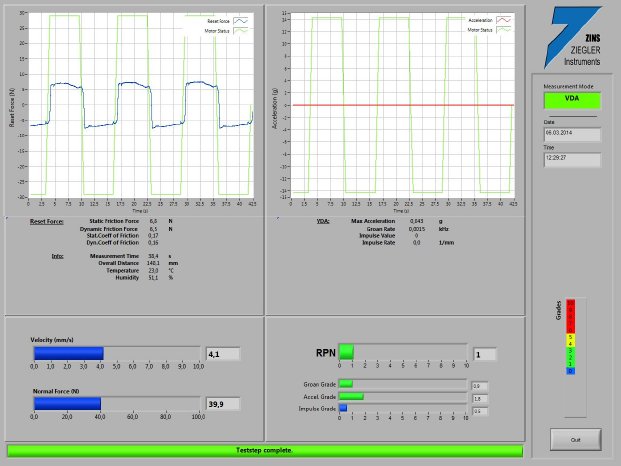

Pictures 1 and 2 (see attached) show the results of a friction pairing between PA66 GF30 and a PC/ASA compounds from ROMIRA ROMILOY® 6020/04 (tribological functionalized) compared to ROMILOY® 6020 (standard grade). The reduced friction resistance between the functional partners is clearly evident.

The most recent anti-squeak studies of various new formula-tions of PA66 GF30 based on a stick-slip test gave a risk priority number of between 1 and 2, which indicates a very low squeak risk under room temperature conditions. ROMIRA's development work is currently focusing on seating applications in vehicles with mounted and built-in parts that are in contact with synthetic leather.

###

Text approved – Specimen copy requested

About the ROMIRA GmbH:

The ROMIRA GmbH was founded in 1990 and is an affiliated partner within the ROWA GROUP. As part of this strong combine, we set standards for technical plastics with our profound competence and synergetic know-how.

Direct media contact and additional information:

Menyesch Public Relations GmbH

Thierry Krauser

Kattrepelsbrücke 1

20095 Hamburg/Germany

Tel.: +49 40 36986313

Fax: +49 40 36986310

E-Mail: rowa@m-pr.de

Enquiries:

ROMIRA GmbH

Dr. Daniela Tomova

Siemensstraße 1-3

D-25421 Pinneberg

Tel.: +49 4101 706 317

E-Mail: d.tomova@romira.de

www.romira.de