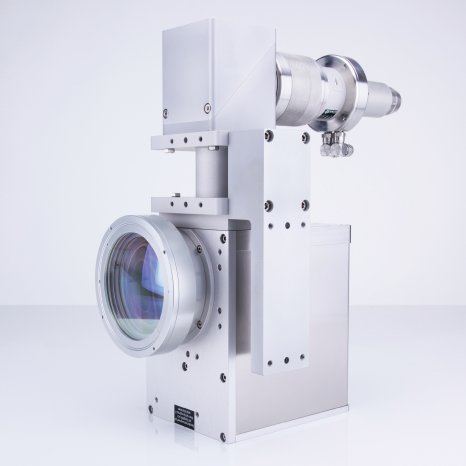

Cost pressure in every industrial sector forces manufacturers to continuously reassess their production processes. Resulting economic efficiencies are ideally combined with process safety and quality. That is precisely the approach of Blackbird's new scan system. Optimized for fiber-coupled disc or fiber lasers with powers up to 8 kW, the intelliSCAN FT positions the beam quickly and precisely for welding of 2D contours. The scan head's compact design, and optionally straight or angled collimator implementations (90° vs. 180° collimator) facilitate straightforward integration in equipment where space is tight. This pre-integrated system is a cost-effective solution for tasks such as welding of batteries in the Automotive sector or welding contacts in electronic component manufacturing.

Remarkably flexible, smart and user friendly

At the system's core are field-proven SCANLAB galvanometer drives with mirrors specially optimized for welding applications. Individual image field calibration and the collimator ring's Z-position adjuster enable exceptionally high precision and easy exchangeability of systems. This is supplemented by automatic self-calibration (ASC), which suppresses drift effects to ensure highest process quality in industrial series production.

The corresponding ScanControlUnit provides diverse bus options for communication and safety, as well as interfaces for image processing systems. Its very user-friendly, intuitive software makes it an optimal solution packet for 2D welding applications. Comprehensive drawing functions and CAD interfaces allow easy set up and optimization of all 2D scan contours for processing. And you can freely program parameters such as laser power interpolation along 2D contours, or oscillation of the laser beam. Delivery includes not only the system's components, but also introductory training and installation support to ensure timely deployment.

"With this new product, customers get a cost-effective, robust system solution for their 2D welding applications that they can quickly and efficiently integrate into industrial welding systems," explains Dr.-Ing. Wolfgang Vogl, CEO of Blackbird Robotersysteme GmbH.

About Blackbird Robotics:

As a subsidiary of SCANLAB, Blackbird Robotersysteme GmbH offers solutions for remote laser welding with scan optics. These solutions enable seamless integration of mirror-based beam deflection units into industrial manufacturing systems, particularly robot cells. The company's core competence is development of high-performance control technology and intuitive user software. In combination with 2D and 3D optics from SCANLAB, Blackbird provides a broad array of pre-integrated solutions for mechanical and plant engineering, automotive production and numerous other manufacturing industries around the world