USP lasers are ideal for ultra-precise micro-machining of diverse materials, because cold ablation allows particularly fine, targeted material removal. To achieve industrial-scale productivity, USP lasers are best combined with ultra-fast scanners – e.g. a polygon scanner. In 2014, SCANLAB introduced its hybrid polygon scan system.

Polygon scanners are particularly advantageous for line-oriented full-surface processing of workpieces – at fine resolutions and with freely definable patterns and structures. Thanks to the high speed, these systems can considerably slash material processing times. USP laser processing applications range from structuring touchscreen surfaces or solar cells, to micro-drilling and processing of electronic components, glass and plastics, as well as sensor manufacturing.

"We see great potential in the polygon scanner market, so it's natural to position ourselves here accordingly. Next Scan Technology's expertise suits our approach well and our products complement each other superbly," says SCANLAB CEO Georg Hofner regarding the successful acquisition.

Broad competence in polygon scanners

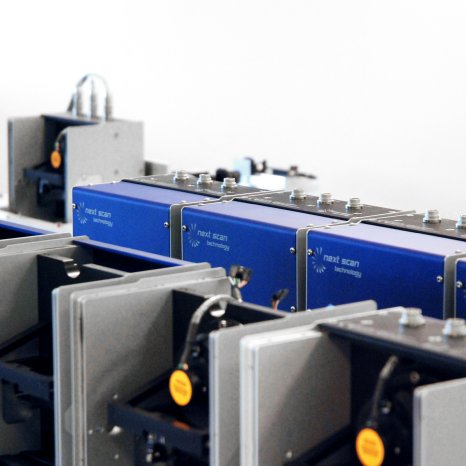

SCANLAB continues its strategy of steady growth by fully acquiring Belgium-based Next Scan Technology with its approximately 10 employees. The result is a polygon scanner competence center with a line of systems for diverse applications.

“Amid rising demand for polygon scanners, Next Scan Technology needed to increase manufacturing capacity and set up worldwide sales, marketing and customer services, while strengthening its management team. SCANLAB's global infrastructure and operational excellence makes it a perfect match to address new market opportunities – via smart cross-over designs using galvo, polygon and mirror F-theta technology,” comments Next Scan Technology managing director Lars Penning on the future collaboration. “Together we'll offer the best of both worlds in scanner systems for challenging high-throughput applications.”

About Next Scan Technology:

In 2009, it became clear that economically viable ultra-short-pulsed laser micro-machining would require high average power lasers and very high speed scanning systems. The management of the Dutch/Belgian start up Next Scan Technology realized that well-established technology in demanding industries as high performance laser printers could be adapted to the needs of this new laser material processing market.

At Laser World of Photonics 2011 in Munich, Next Scan Technology was the first to introduce a polygon based scanner system compatible with high power ultra-short-pulsed lasers. From 2013 to 2015, all business activity was transferred to and extended at the new facility in Evergem, Belgium.

www.nextscantechnology.com