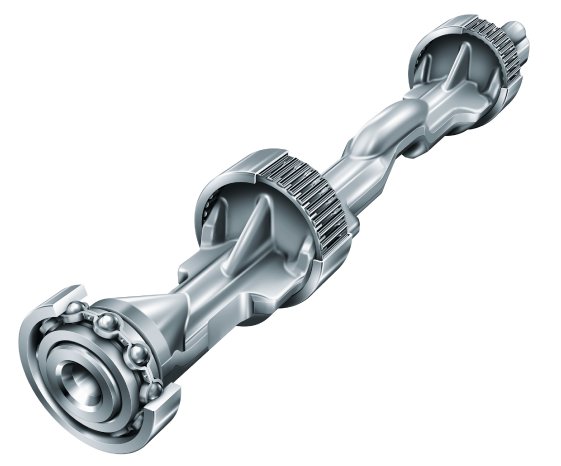

Lightweight balancer shafts with rolling bearing supports are enjoying increasing popularity since they contribute to cutting fuel consumption and CO2 emissions and comply with the trends for downsizing and downspeeding of engines associated with this. They increase the smoothness of running of internal combustion engines and reduce fuel consumption. The rolling bearing supports with reduced friction characteristics enable a significant improvement in energy efficiency compared to the plain bearings that were previously used. This means the power consumed internally an four-cylinder diesel engine already in volume production is reduced by up to 1.5 kW (2.0 horsepower). This design, which is increasingly being used in engines, also considerably reduces the requirement for oil cooling and makes the previously obligatory pressure lubrication no longer necessary. This means lightweight balancer shafts with rolling bearing supports are particularly suitable for engines with start-stop systems. The rolling bearing supports also enable a new optimized mass layout of the balancer shafts with a mass that is reduced by around one third. This means the two balancer shafts mounted in an engine, which run at twice crankshaft speed due to the design, alone reduce engine weight by more than a kilogram. The filigree design minimizes the shaft's rotational inertia and, thus, in turn reduces the driving forces required.

The lightweight balancer shaft with rolling bearing supports celebrated its premiere in Daimlers' OM 651 four-cylinder diesel engine, which was awarded Engine of the Year in 2009. The balancer shafts of other modern engines are now equipped with rolling bearing supports such Fiat's two-cylinder TwinAir engine, which has received this year's Engine of the Year award. Last year, the lightweight balancer shaft with rolling bearing supports received the Steel Innovation Prize.