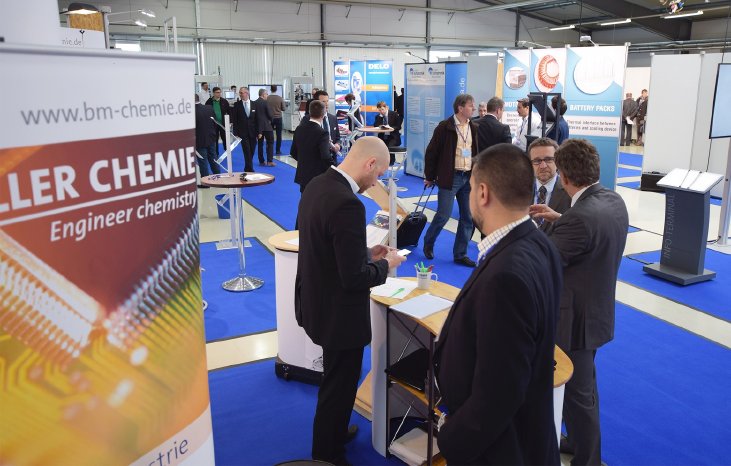

From potting batteries and electric engines to new, high temperature resistant potting materials for power electronics all the way to optical bonding: On the fourth TechDays it became clear, how important efficient dispensing technology and intelligent potting materials are with regard to central trends and developments today. This was also reflected in the number of visitors and exhibitors: Approximately 500 guests from 24 countries were on site this year – that’s a surplus of 25 percent compared to the previous event. In the course of the accompanying specialist exhibition, overall 21 material manufacturers and system partners presented their innovations.

“We have always been an exhibitor at the Scheugenpflug TechDays,” explains Jochen Frank of WEVO-CHEMIE. “Over time, the event grew from a small in-house exhibition to a notable industry get-together. Due to the suitable visitor structure, we receive a lot of qualified requests, which frequently turn into concrete projects.”

High performance battery potting

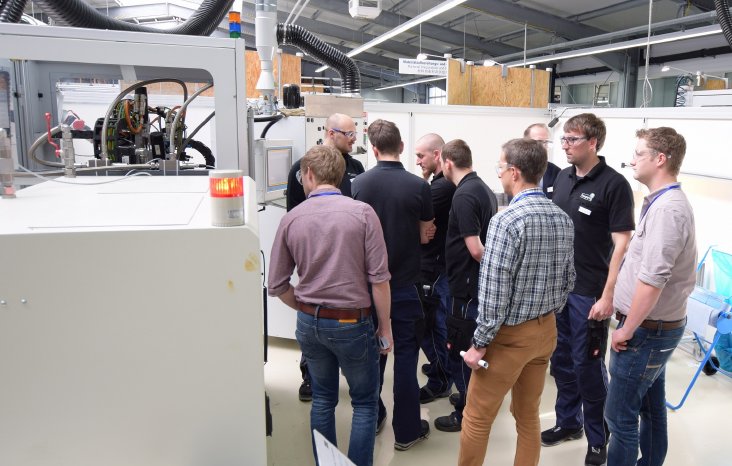

A central point of attraction for the visitors was the Testing and Application Center of Scheugenpflug, in which live potting performances with the latest adhesives and potting materials were conducted. Scheugenpflug’s new solution for potting batteries for electronic vehicles was very well received: The company specifically developed a volumetric high-performance dispenser that allows for peak flow rates even with very abrasive and paste-like potting media. In the course of dispensing tests with a highly viscous material (100.000 mPa∙s), a dispensing rate of 20 ml/s could be achieved.

Also, the newly designed DispensingCell has been introduced; a compact entry-level solution for thermal management tasks. This fully preconfigured and parameterized dispensing and potting cell is precisely adjusted to tested and approved thermally conductive materials prior to delivery. Apart from the fast availability of the system, users profit from a good price-performance ratio as well as a fast production launch, thanks to Plug and Produce.

Practice-oriented specialist presentations

The TechDays program was rounded off by a broad spectrum of specialist presentations in German and English. In addition to current application examples like optical bonding or potting of winding goods in the context of eMobility, the issue of process optimization was a central topic.

Apart from the extensive event program, the TechDays offered plenty of opportunities for concrete exchange: “In my opinion, personal contact is a very important factor,” says Heiko Weihmann of Infineon Technologies. “The event offered me the opportunity to get to know my contacts at Scheugenpflug in person and to settle some questions in direct conversation. I already participated in the last TechDays and will probably participate again in two years.”