- Innovative cell structure promises 0.6%abs gain of efficiency compared to 3-busbar cells

- Lower series resistance provides higher fill factor of up to 0.3%

- Reduction of silver consumption on the front and back side of approx. 75% compared to a 3-busbar screen printed cell

- Finish of the last project phase with production-ready machine in 2013

SCHMID presents the prototype of its Multi Busbar Connector and a Multi Busbar Module at PVSEC, booth B06 in hall A.03. The sales launch of the production-ready machine is planned for 2013.

The multi busbar technology is based on an innovative cell structure which completely manages without the well-known wide silver busbars. The consumption of the expensive material on the front and back side compared to a conventional cell is thereby reduced by 75%. Less shadowing promises an efficiency increase of 0.6%abs.

The multi busbar technology obtains the best results with SCHMID processes and equipment for the production of a cell with a selective emitter (inline selective emitter technology InSecT) and approx. 40 μm wide plated contact fingers (contact-free high-efficiency metallization technology HiMeT). The key processes for this cell manufacturing technology are the contact-free inkjet printing as well as wet bench etching processes and plating technology. The cell back side is 100 percent silver-free thanks to SCHMID's TinPad technology.

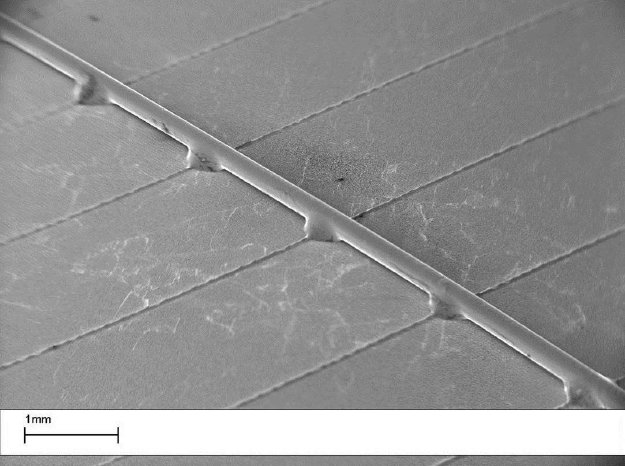

The Multi Busbar Connector subsequently attaches 15 wire busbars to the front side of these basic cells using contact-free infrared soldering and at the same time joins multiple cells into a string. The smaller distances between the wires reduce the series resistance of the cells and thus increase the fill factor by up to 0.3%.

The result is a high efficiency multi busbar module. It combines all resource-saving and efficiency increasing technologies SCHMID has developed for the front side in the last years. Therefore the technology leader is providing urgently needed solutions for reducing the costs in photovoltaic production.