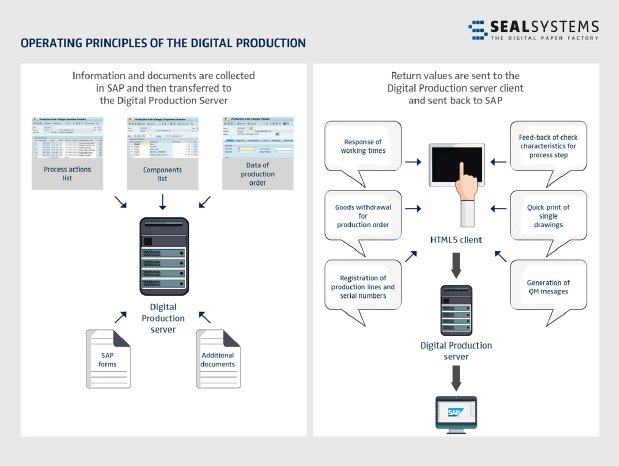

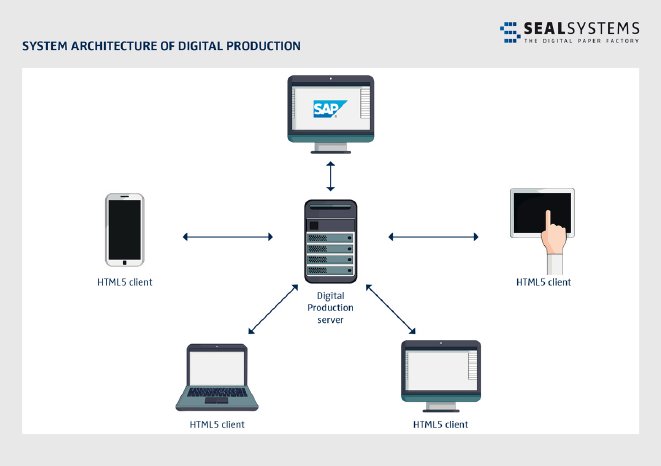

Production processes which use paper can be cumbersome and prone to error. Conversion to digital processes makes them faster, safer, and more up-to-date. Printing, sorting and distributing print orders becomes a thing of the past, the primary tools now being the PALO server and the clients connected to it.

Release directly in SAP enables all employees to receive their order information and documents immediately, on their screens (PC, tablet or smartphone) at their workstation. These screens are not only used for display, but also serve for process and inspection feedback, and for the capture of charges and serial numbers. This feedback is captured directly in the corresponding client and then recorded in SAP. This direct feedback makes the current status of the production process transparent for all involved.

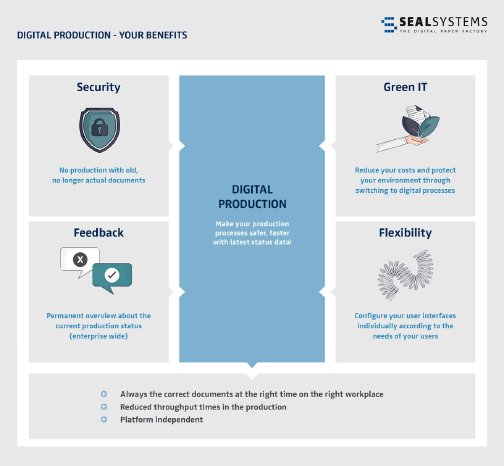

The advantages of paperless production are the following:

• No printing of orders and drawings

• Time saved

• Savings in costs and personnel deployment

• Less paper used (Green IT)

• Fewer manual work steps

• Improvement to the entire production process

• No manual distribution of documents

• Feedback sent directly, without the need for paper

• More transparent production processes

All user interfaces are widely configurable, and yet so intuitively operable that they can also be easily handled by employees who are not IT-savvy. Furthermore, videos can be utilized for complicated production processes. Paperless production likewise offers the possibility to send 3-D models from CAD, and other important documents for the production process, to employees or clients. Paperless production has, then, all the advantages – and none of the disadvantages – of paper.