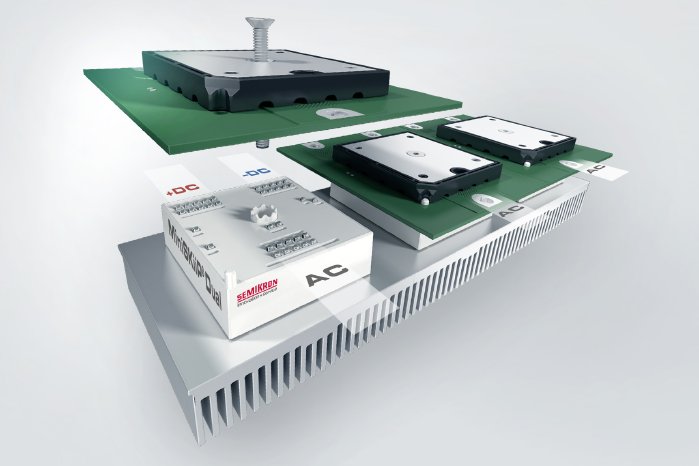

For the first time MiniSKiiP Spring Technology is available for power ratings higher than 40 kW. The benefits: lower material costs as compared to traditional inverter designs because the expensive bus-baring of the load connectors can be replaced by a cost-efficient PCB connection. In combination with a fast, solder-free assembly, this allows for reducing the system costs by up to 15 percent. The spring contacts make the layout of the printed circuit board (PCB) simpler and more flexible because the PCB does not need holes for soldering pins. Also, the springs allow for a more flexible connection between the PCB and the module than a soldered joint, which adds extra benefits particularly under thermal and mechanical stress.

The MiniSKiiP Dual's output of up to 90 kW requires higher current-carrying capability of the PCB, which e. g. can be achieved by using a 210µm standard metal coating on the PCB. This allows for load currents up to 180 ARMS, which used to be reserved for modules with screw mounted busbars.