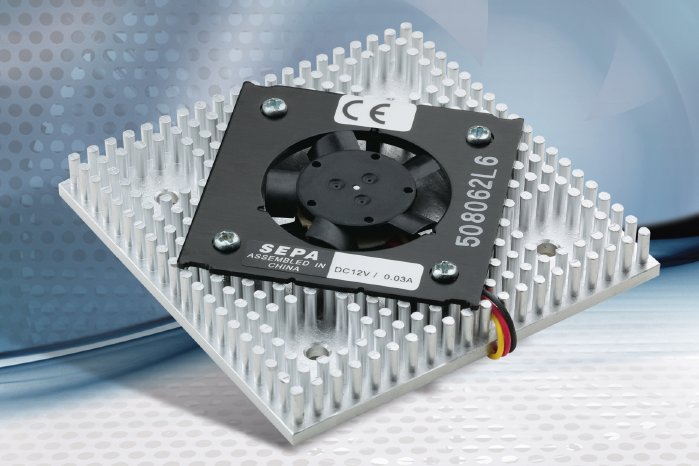

The new generation of the Powerbloc Kühligel produced by Alutronic is made from pure aluminium (Al 99.5 DIN EN1050) and thus has an exceptionally high thermal conductivity. In comparison to extruded heat sinks, the thermal conduc-tivity is 30% higher, in comparison to die-cast heat sinks it is even 40% higher. The cooling pins are manufactured by extrusion. The low-waste manufacturing method is simple and economical.

In addition to standard sizes, special shapes can be realized at predictable tool costs, e.g. the base shape can be square or produced according to the custom-er’s requirements. The maximum size of the base plate is 200x200 mm, with a minimum base thickness of 1mm (flatness ≤ 0.1mm). The customer has the choice of either a round, elliptical or polygonal pin shape. The maximum possible pin height is 300 mm and the smallest possible pin diameter is ≥1 mm. The Kühligel is available in both blank aluminium or anodized in colour.

Special requests can be realized by mechanical processing. Double-sided

adhesive heat conduction pads (TCT) or thermally conductive adhesive (HERNON 746) can be used for mounting. Other mounting options are available on request. The effectivity of the Kühligel is increased significantly by screw mounting the fan. With the new generation of heat sinks, special screws are used to mount the fans without involving expensive mechanical processing. The applied thread-locking fluid fulfils two tasks: it serves as a lubricant when screwing in the screws and secures any possible chips from falling out. If the height is limited, the fan can be lowered or attached at the side.