Halle: 5 / Stand-Nr.: 5C13

Automated inventory recording, item documentation and quality control - Sereact is presenting its AI monitoring platform Sereact Lens to a wide audience for the first time at LogiMAT. In Hall 5, Stand 5C13, visitors can experience live how the AI creates full transparency in real time about the condition and properties of all stored products and eliminates errors due to manual intervention.

Many companies struggle with inaccurate inventory data and time-consuming manual checks. With Sereact Lens, these challenges can finally be solved. The AI-based monitoring platform automates inventory monitoring, detects anomalies and enables inventory on the fly - easily, quickly and reliably.

Sereact's innovative AI software works in combination with a camera.The entire system can be deployed ready for use in central areas such as order picking or picking stations within an hour. Containers are automatically scanned and the platform compares the recorded data with the stock levels in the WMS in real time. This enables up-to-date inventory control at all times, reduces out-of-stocks and prevents overstocking.

Anomaly and quality control

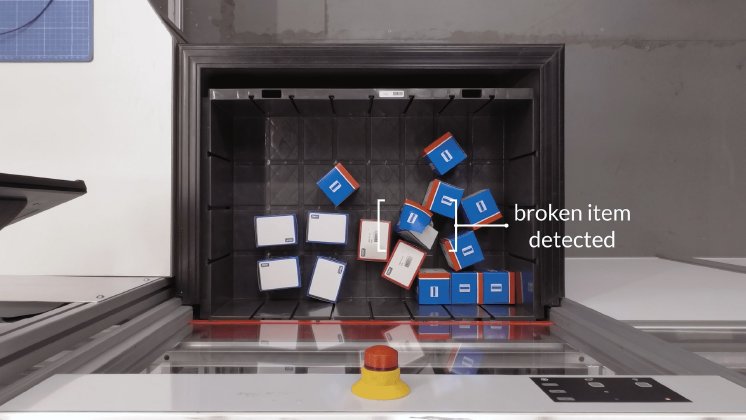

Sereact Lens automatically detects damaged items or items incorrectly assigned to an SKU container, as well as waste in storage bins. This data is sent to quality control or incoming and outgoing goods, so that adjustments can be made quickly. This significantly increases process quality.

Optimized item documentation

The platform documents the condition and number of items at goods receipt and goods issue. This ensures that shipments meet quality standards and that complaints can be checked efficiently. Missing or damaged items are easily identified and the condition of deliveries is checked before they are put into storage.

Efficient returns management

Sereact Lens also saves valuable resources when it comes to returns. The platform automatically recognizes whether a return needs to be checked or can be put back into storage straight away. Packaging damage, signs of use or opened items are detected and the return is compared with the shipping documentation. This eliminates unnecessary manual initial checks.

Advantages for intralogistics

Sereact Lens optimizes warehouse processes, minimizes errors and reduces costs. Real-time data in cloud-based dashboards enables well-founded decisions and continuous improvements. Companies benefit from more efficient processes, higher customer satisfaction through precise deliveries and long-term competitive advantages.