The project, which will run for 2.5 years, is pursuing an innovative approach to integrating PLA-degrading enzymes such as proteinase K and ICCG into plastic products. These enzymes are bound to the surface of zeolite, a porous carrier material that acts as a carrier for the enzymes, using an adhesion promoter peptide. The enzyme-loaded zeolite is then processed into a PLA zeolite masterbatch in a specially developed extrusion process. The enzyme complex is introduced into the PLA matrix in an inactivated form. The enzymes are only activated by a change in the environmental conditions and by abrasion or embrittlement of the material. This significantly increases the degradation rate of the PLA.

“Through the targeted, switchable activation of the enzymes, we want to offer a solution that enables the industry to produce plastic products with high mechanical stability, but which are degraded more quickly and efficiently in the environment after their use phase,” explains Alexander Rusam, scientist at SKZ and head of the project.

First successful results

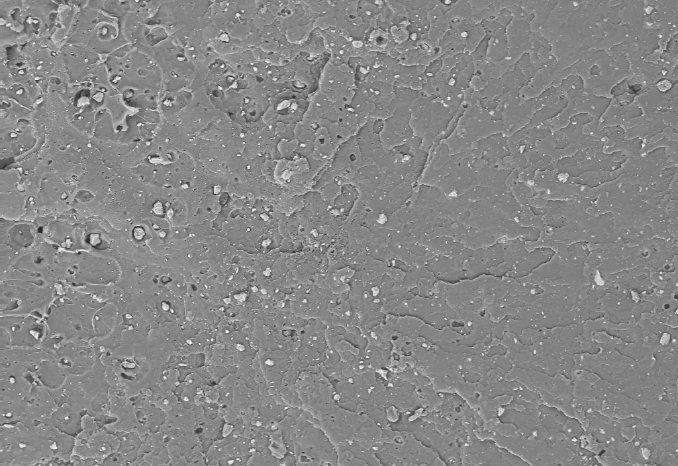

The first tests of the project have already delivered remarkable results. Using a microextruder, test specimens made of PLA and fine zeolite powder were successfully produced. The zeolite showed an even and homogeneous distribution in the component. It was also found that the addition of the enzymes had no negative impact on the mechanical properties of the PLA - an important milestone for the development of a marketable product.

“These initial results confirm the feasibility of the process and open up promising prospects for the development of plastics that are both environmentally friendly and functional,” continues Rusam.

The project is helping to create a more sustainable future for the plastics industry by providing solutions for the degradability of plastics without compromising their performance during use. The project team plans to further optimize the technology and prepare for industrialized application as the project progresses.

More about the area Material development

The SKZ is climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.