hydraulics actuators to deliver the required forces. However, after working closely with a major European manufacturer of food & beverage packaging solutions SMAC has designed an actuator that is a hybrid of electronics & pneumatics to deliver the considerable benefits of both.

Until now both technologies have a number of advantages & disadvantages:

Whilst pneumatic devices offer a relatively high degree of force in a compact sized component there are a number of significant draw backs to be considered:

A high degree of accuracy & repeatability is difficult to obtain.

True positional programming is not possible. Whilst over the years pneumatics manufacturers have introduced any number of mechanical clamping arrangements, braking systems and other nefarious devices none have been truly successful. The automatic change of machines to new & different processes has not been possible without some form of manual intervention. Relative to electric & electronic devices pneumatics offer a low number of cycles due to shock & wear during cycles. Extremely soft / delicate contact with components & work pieces is not possible due to the dynamic sealing arrangement which is inherent in such pneumatic devices. Extremely noisy - compressed air when being exhausted to atmosphere makes a lot of noise! So much so that legislation has recently been introduced to ensure it is kept at acceptable and safe levels.

Compressed air and pneumatic controls are notoriously inefficient. Whilst the components are relatively low cost the actual running costs are considerable and should not be under estimated. However, they do have significant advantages of international dimensional standardisation and also the wide availability of pneumatic components.

They are truly ubiquitous and be can be sourced & purchased in any town anywhere in the world - 'off the shelf'.

The major disadvantages with electric & electronic actuators when compared against pneumatic & hydraulic actuators are: Price - The unit or component costs are circa 40%+

higher than a conventional pneumatic cylinder. However, prices of electric solutions are rapidly decreasing from the majority of manufacturers. The other major drawback, up until now is the relatively low degree of force generated. They are however, extremely quiet and in comparison extremely energy efficient - a major point for consideration with the current high profile and emphasis on global warming, climate change issues & carbon footprints.

Back To the Future To overcome these disadvantages SMAC has gone 'back to the future' with a reliable, tried & trusted idea that has been reinvented, updated and improved. 'Air over oil' and

'accumulator' systems have been used for many years. This is where a pneumatic and hydraulic cylinder (or 2 pneumatic cylinders) has been connected together. One actuator to deliver the movement or travel to the desired position and the other actuator to deliver the required force. SMAC is now the first manufacturer to apply this idea to electronic actuators.

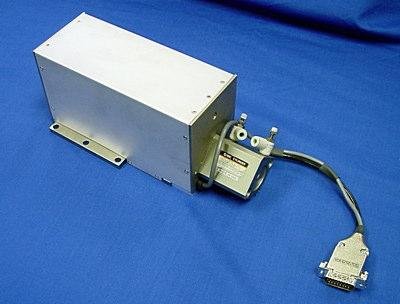

The SMAC Hybrid Solution A small pneumatic actuator (circa 20mm dia & 10mm stroke.) is attached to the rear of a SMAC electronic actuator. The front of piston rod is connected to the rear piston rod of the electronic actuator - thus creating the hybrid. The electronic actuator can then be controlled as normal delivering all the advantages and flexibility of speed, precision, accuracy, repeatability and long life. When and only when the electronic actuator is in the required position - air is switched on and applied to the small pneumatic cylinder. It is this function that then delivers the higher force required. Due to the fact that the air is only applied once the electronic actuator has reached the desired position and then switched off when no longer required there is virtually no wear to the pneumatic sealing arrangement. This enables an exceptionally long life cycle - at least that equal to the electronic actuator. As the pneumatic actuator is small in both diameter and stroke the amount of compressed air used is minimal.

This unique solution was recently successfully used to replace a number of 63mm diameter pneumatic cylinders with SMAC electronic Moving Coil Actuators (MCA) for an ultrasonic welding application on drink cartons. SMAC created the exact profile required using a high speed approach, then using the unique 'Softland' function to place the component in position then apply force with the pneumatic actuator whilst the welding took place.

Advantages The advantages and improvements to the system were considerable. Whilst using the 63mm diameter pneumatic cylinders on the conventional solution external, electrical sensors were required to detect position. Due to the fact the SMAC actuator has inherent positional control & feedback these were no longer required. This significantly reduced the amount of external wiring required. It also enabled the customer to increase the cycle time as previously the system had to wait for confirmation from the external sensor that the end of the pneumatic cylinder stroke had been reached. With the SMAC solution the next part of the cycle could commence immediately after the electronic actuator had moved off - saving valuable milliseconds.

Further to this the two biggest problems for the customer were also solved. The first one being noise. With a number of large bore pneumatic cylinders performing a high number of cycles in an enclosed space the noise was above that of the legal limit & legislation.

Therefore the operators were required to wear ear plugs and ear protection equipment.

This was no longer required with the SMAC solution. Secondly, due to the high number of cycles involved and the impact and 'shock' at the end stroke of the conventional pneumatic cylinder the life of the actuators was low - they were replaced 4 times per year as part of a preventative maintenance routine. This is no longer required with the electric solution as they are good for many, many millions of cycles.

Summary To briefly summarise the SMAC 'Air over Electric' hybrid solution has taken the best from both electronic & pneumatic technologies and delivered them into a single package.

No longer the need to compromise the need for speed, position and accuracy with that of force. It also brings total & true programmability, exceptionally long life, low noise and a significant improvement in energy & efficiency in a highly cost efficient package.