(www.sms-group.com) the order for the upgrade of their existing beam blank caster. The six-strand machine, built by Concast in 2000, casts billet, bloom and beam blank sections of various sizes. It was originally designed for a nominal capacity of more than 1,000,000 tons per year, provided with a prepared seventh strand and the possibility to increase production accordingly. Against the backdrop of new market requirements, the seventh strand is now going to be equipped with the CONDRIVE oscillation drive for beam blanks and the primary water cooling plant will be upgraded.

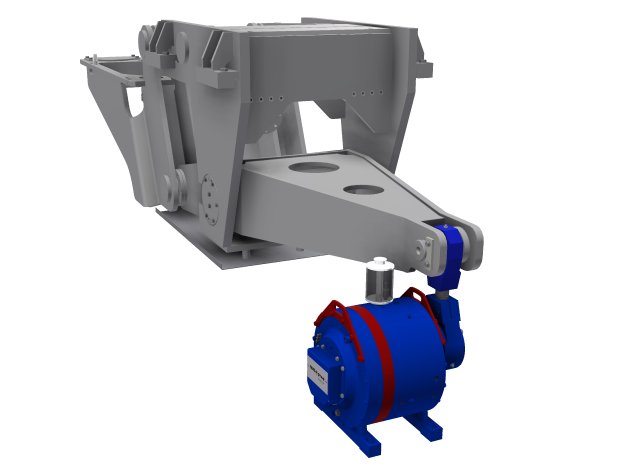

CELSA chose to install a new generation of mold oscillation mechanism: the CONDRIVE electrical direct drive, which is part of SMS Concast’s Industrie 4.0 portfolio. The CONDRIVE technology is based on the principle of a direct servo drive motor. The system is virtually maintenance-free and provides excellent precision in controlling the oscillation torque. Unlike other drive systems for oscillation (including hydraulic servo cylinders), the CONDRIVE combines simple design with online adjustment and monitoring of the oscillation curves.

The project schedule for the upgrade is very tight: the installation of the new equipment is planned to be completed by the end of 2018. CELSA plans to install the CONDRIVE on all other strands after a first trial period.