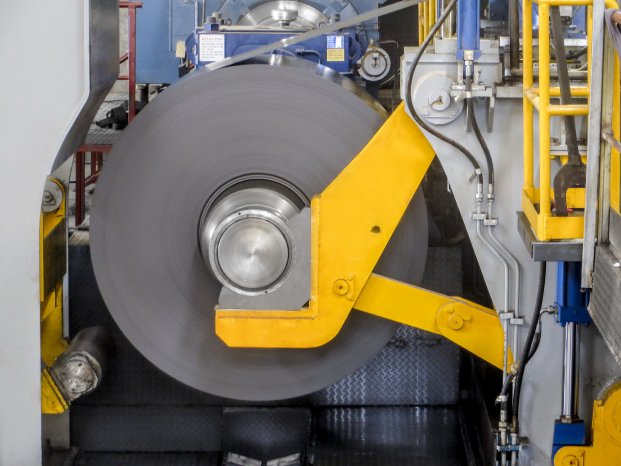

The new CCM® is a twin-stand reversing cold mill, completely supplied by SMS group including the X-Pact® electrical and automation systems and the media plants. During the order placing, ISL attached importance to SMS group supplying the entire mechatronic systems from a single source in order to ensure troublefree coaction of mechanical equipment and automation system. The short commissioning time proofs this strategy right.

Quality components like the complete mill stands, drive trains and media systems from German manufacturing ensure the quality of the strips rolled. CVC®plus roll shifting technology and two X-Shape flatness measurement rolls as important components of the X-Shape flatness measurement and control system complete the technological components.

The new CCM® increases ISL's production significantly. With the commissioning of the second cold rolling mill, ISL's rolling capacity has increased to approx. one million tons per year, depending on the product mix, thus making the company the largest producer of cold rolled and galvanized products in Pakistan. The new mill is designed to roll strips with a maximum width of 1,250 millimeters down to a final thickness of 0.15 millimeters.