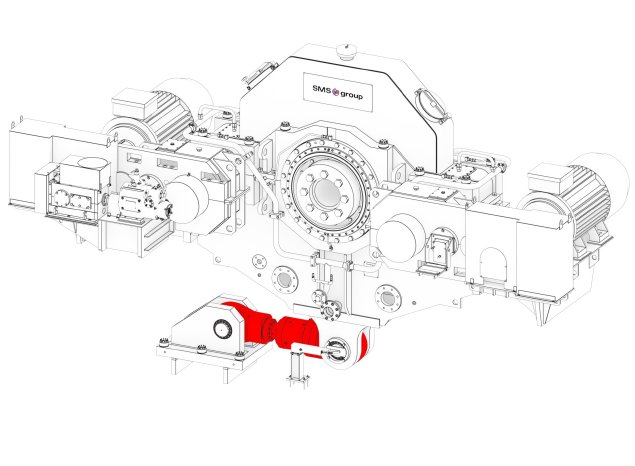

SMS group’s scope of supply comprises a new converter tilt drive system, a hydraulic torque retainer, performance of the erection work, supervision of erection and commissioning.

The AOD converter to be delivered by SMS group will be equipped with a new tilt drive system featuring a new gearwheel design developed by SMS group. The optimized tooth and flank profile ensures the pressure is distributed evenly across the whole load spectrum, while the surface pressure itself is far lower than with conventional wheels. With this new design, the drive torque capacity and thus the productivity of the converter can be increased without the need for additional space.

The SMS group competence center for industrial gear manufacturing, based in Hilchenbach, developed the new gearwheel design and manufactures industrial gear units such as these for worldwide applications.

The purpose of installing the hydraulic torque retainer from SMS group is to minimize the destructive forces on the gears, bearings and foundations during the AOD converter blowing process. The use of the new electrohydraulic torque retainer means the previously uncontrollable dynamic loads, to which the converter equipment as a whole is subjected, are significantly reduced.

Sandvik Materials Technology was impressed with the positive results of the new torque retainer in use at another European customer of SMS group.

Sandvik Materials Technology operates around the world as a developer and producer of advanced stainless steels and special alloys.