The modernization helps Severstal boost the capacity of its line as a result of the higher availability and increase the quality of the strip edges. Improvements in burr-free cutting and edge uniformity are particularly obvious when processing soft materials.

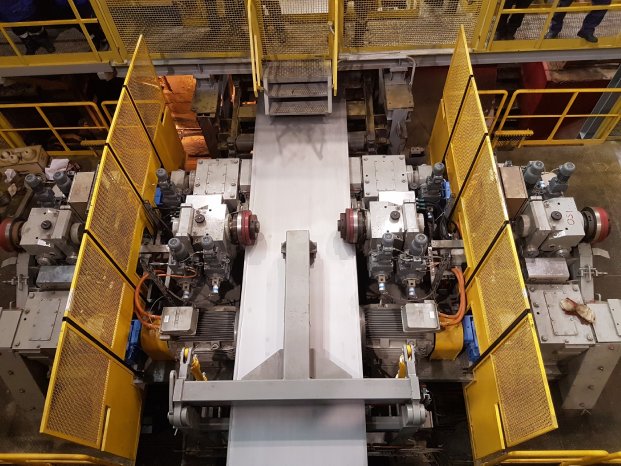

At speeds of up to 360 meters per minute, the machine trims the strip edges in the exit section of the pickling line by means of two circular knives arranged on both sides. At the same time, it cuts the 1.2 to 6.0 millimeters thick hot strip to the desired width, which may vary from 700 to 1,650 millimeters. An integrated scrap chopper cuts the separated seams into small pieces. The twin-head design of the side trimmer offers the advantage that trimming knives in maintenance position can be changed while production is going on.