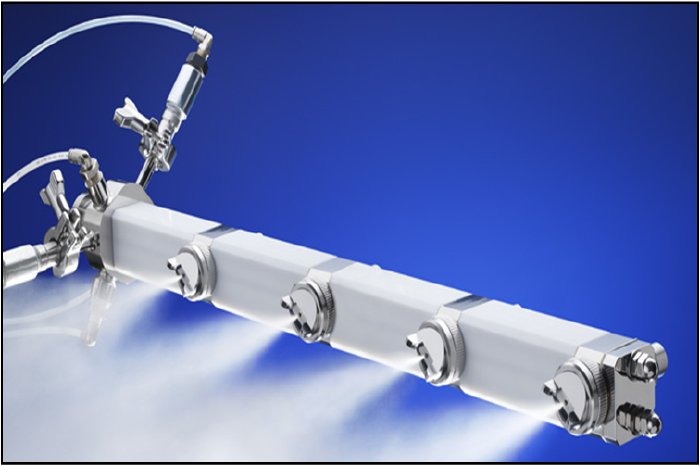

Spraying Systems Model 54000 header can improve tablet coating processes immediately. Product scrap and rework due to film coating issues can be reduced by more than 15%. Plus, less time is being spent on tablet inspection and sorting. Another benefit is reduced maintenance time. Saving about 30 minutes per tablet batch for clean-up and spray nozzle alignment and annual savings of US$25,000 and a payback period of about 10 months speaks for themselves.

The Model 54000 header features a modular design and can accommodate up to 6 spray nozzles. Routine maintenance can be done without special tools. A superior surface finish reduces contamination risk and simplifies maintenance.

VMAU nozzles offer independent control of liquid, atomizing air and fan air for fine tuning of spray capacity, droplet size and spray coverage. A wide range of spray set-ups, including anti-bearding versions, are available.