It takes a high degree of creativity and expertise to be confident of realizing an assembly line like the one that has been in operation at Stäubli Electrical Connectors since the third quarter of 2022. To understand what the Stäubli team and the plant manufacturer involved have achieved, it is necessary to look at the range of tasks performed on the assembly line, where sockets and plugs are fitted with a MULTILAM in a multitude of variants.

Stäubli’s patented MULTILAM contact technology boasts unrivaled electrical and mechanical properties and exemplifies the highest standards of quality and reliability in electrical connector manufacturing. In a production context, this means robot-supported zero-defect precision assembly in the tolerance range of 20 to 30 mm, with widely fluctuating batch sizes of 20,000 to 2,000,000 units. Further, when demand and workloads are high, the system can be expanded, and a specific item can be assembled simultaneously on two parallel production lines.

Mobile assembly modules with integrated robots

Identifying suitable robots for this high-precision assembly was relatively easy for Stäubli, as the most accurate machines on the market are made by the company itself. Five of them (four six-axis TX2-40s and one TS2-40 SCARA) now work in the assembly plant at Weil am Rhein. There was initial skepticism about the feasibility of docking a mobile assembly module plus robot, together with all its complex peripherals, onto the line within a one-minute time limit and starting production without having to first calibrate the robot or make other adjustments.

Not possible, said many. Oh yes it is, said Stäubli, and then provided the proof. John Dallapiccola, Managing Director Stäubli Electrical Connectors Weil am Rhein, describes how the squaring of the circle became possible: “The concept of this unique system is based on the utilization of synergy effects within the Stäubli Group. We have our own precision robots and innovative interface solutions, which in this case were key to the realization of the plant. And, of course, we had a brilliant idea.”

Connector technology and precision couplings: the key to realizing this advanced concept

What Dallapiccola means becomes clear on closer inspection. The decisive factor for the realization of this concept was the ability to dock the mobile modules onto the line with precision down to the hundredth of a millimeter. The time factor played an additional decisive role. The specification was to position the module manually, center it automatically, lock it in place and set it to work. Production start-up was to be within 30 seconds.

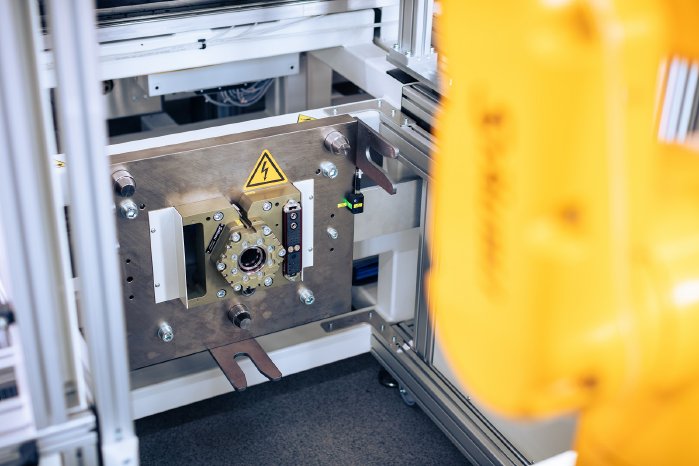

During this short period, the energy and compressed air supply must start flowing to all components of the module. The robot, parts feed, separation and image processing, power, signaling and pneumatic connections of each component must be connected reliably and simultaneously. This is where the CombiTac modular connector from Stäubli Electrical Connectors comes into play. Hovering next to both the assembly station and the mobile module, the CombiTac automatically connects all power and media circuits in sync with the docking process. High-precision mechanical guides and a pneumatically actuated quick coupling supplied by Stäubli Fluid Connectors ensure that the mobile module is correctly positioned on the assembly line.

Four- and six-axis robots mounted on mobile modules

In the current expansion stage, the complete assembly line consists of no fewer than 12 modules linked to each other by means of a Beckhoff XTS linear transport system. Four more modules are to be added later. There are currently 20 magnetically driven movers in operation on the transfer system, which move along a route consisting of fully integrated motor modules. An industrial PC with TwinCAT automation software enables independent control of the movers with individual motion profiles. The degree of precision – one hundredth of a millimeter – is yet another remarkable feature of the system.

Fixtures specific to different parts are located on the movers, which the first two Stäubli six-axis robots on modules 1 and 2 equip with a MULTILAM and, depending on the variant to be produced, with a plug or a socket. “Gripping and positioning these miniscule components with dimensions in the millimeter range requires the highest precision from the two TX2-40s mounted on their mobile modules, and it also has to be done with maximum dynamics,” says Production Manager Sebastian Wiech. “The six-axis machines perform this demanding task with aplomb.” Asyrill vibration platforms with image processing systems suspended above them ensure process-reliable parts supply as well as the transmission of gripper positions to the robots.

The components then reach the processing station, where the MULTILAM is married to the socket or plug. Depending on the variant, further work steps follow. If, for example, a socket ring has to be fitted, this task is performed by an ultra-compact Stäubli TS2-40 SCARA. The four-axis machine is impressive not only for its small footprint, but above all for its impressive precision and dynamics.

One hundred percent quality control

Stäubli connectors are among the best of their kind in the world, so, as you would expect from this manufacturer, every connector undergoes one hundred percent quality control. Supply Chain Manager Jan Schwarzwälder: “Ensuring product quality is one of the most important tasks performed by this production line. To this end, we integrate quality assurance into several sub-steps. We fully document the quality produced, of course, and can guarantee traceability on an individual part basis.”

In the process, each connector goes through a mating force test, in which the specified tolerances must be adhered to precisely. Missing or duplicate MULTILAM components would be immediately detected by the system.

At the end of the line, a camera-based final inspection takes place. Sebastian Wiech: “To keep cycle times to a minimum, we have equipped the station where the pass/fail parts inspection takes place with two modules. A camera system measures the inner diameter and checks the number of pins on the MULTILAM.” The handling of completed parts at this station is the task of another Stäubli TX2-60. With its high dynamics, the six-axis machine ensures compliance with the specified cycle time.

Short changeover times thanks to synergy effects

The changeover processes on the line are also optimized down to the last detail. Jan Schwarzwälder: “Depending on the complexity of the end product, the changeover time varies from two to a maximum of 20 minutes. We owe these short changeover times not least to the MPS 025 robotic tool changer from Stäubli Fluid Connectors, which operates with a precision of ±1.5 µm and eliminates the need for time-consuming manual changes.”

Currently, the system is running seven product variants, the so-called high-runners for use in e mobility and welding automation. Further variants will follow. Likewise, the integration of a fully automated packaging line is planned, which will further expand the plant’s scope of delivery.

“That’s the beauty of this pioneering system,” says John Dallapiccola with justifiable pride. “Thanks to its immense flexibility, we are no longer subject to any restrictions. We can produce any number of variants and integrate further processes as required. The synergy effects of Stäubli’s Robotics, Fluid and Electrical Connectors business units have played a major role in the realization of this unique assembly plant.”

Text by: Ralf Högel