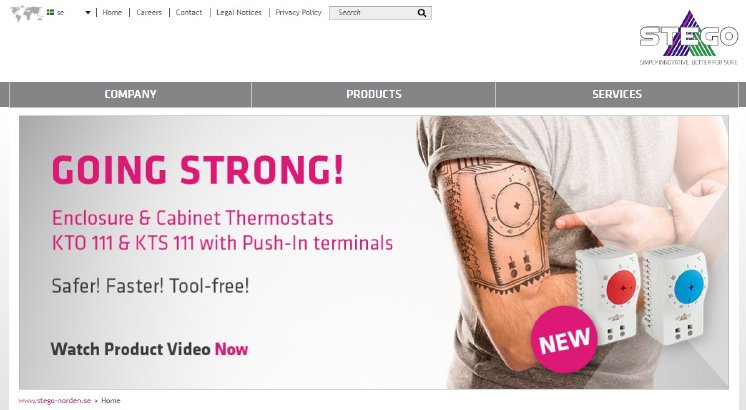

Push-In terminals for faster connection

With the new KTO / KTS thermostats, STEGO has taken the opportunity to adapt its regulators to meet the requirements of the enclosure manufacturing industry. KTO 111 and KTS 111 connect to the power supply tool-free using Push-In terminals on the front of the housing. The terminals provide constant pressure on the connection wires ensuring safety even during transportation of preassembled enclosures. It prevents wires from becoming loosened. Another advantage of the Push-In terminals is a 2/3rd reduction of installation time due to tool-free wiring.

NC and NO Contacts for optimal climate

The mechanical thermostat may appear to be small and possibly unspectacular, however only at a first glance! Thermostats are important components in every enclosure. They regulate the climatization of electronic components within the desired temperature range and thus help protect against harmful condensation. The two new thermostats are designed as two-state regulators with a sensor element made of thermostatic bimetal. The flexible bimetal bends under the influence of temperature and switches a snap-action contact. The KTO 111 is a contact breaker (NC – normally closed - the contact opens when the temperature is rising) for regulating heaters. The KTS 111 is a contact maker (NO – normally open, the contact closes when the temperature is rising) for regulating filter fans, heat exchangers, cooling appliances, or switching signal devices. So, what is the advantage of using a thermostat duo over a thermostat with change-over contact? The combination of two single thermostats (NC and NO) is more economical and allows the user to individually set the temperature ranges for heating and cooling. On the other hand, the change-over contact provides a specific changing point between heating and cooling and is a good choice when space is at a premium.

More air to “breath”

The Schwaebisch Hall, Germany-based company has put a lot of effort into the re-design of the thermostat housing. Now the thermostat has “more air to breath”. Enlarged air gaps on the rear of the thermostat housing ensure an optimized air intake and thus improved response time to temperature changes. Noticeable is also the curved, ergonomic housing design on the front with a large setting dial, which is easier to read and increases safety against unintentional adjustments: the temperature setting can only be changed with a screwdriver. STEGO´s Head of Development Peter Witsch points out the company’s special relationship to the enclosure and cabinet thermostat: “Our company co-founder and former Head of Development Hartmut Eisenhauer developed the bimetal thermostat for enclosures and control cabinets around 30 years ago. Since then, this product invention has become an established industry product. Therefore, we are committed to further extend the product benefits for customers with each re-design.”

Tried and tested in harsh environments

The operating temperature of the thermostats ranges from -45 to +80 °C (-49 to + 176 °F) in an environment with a maximum of 90 % relative humidity (non-condensing). KTO / KTS are developed for protection type IP20 and protection class 2, achieve a verified service life of 100,000 cycles, and are suitable for the following switching currents: AC 250 V, AC 120 V, and DC 24 to 72 V. The maximum inrush current is AC 16 A for 10 seconds. The switch temperature difference is 7 K with a tolerance of ±4 K. They are mounted by the clip for a DIN rail. A special feature of the new thermostats is their suitability for use in high altitudes. The thermostats can be used up to 5,000 meters (in overvoltage category II) and up to 2,000 meters (in overvoltage category III), thanks to the optimized air gap and increased creepage distance. The thermostats KTO 111 and KTS 111 have standard agency approvals, such as safety approvals by UL and VDE.