Jim Walchuck, President and CEO of Zinc One commented, “While this portion of the Mina Grande Sur drill program was designed to determine the extent of the mineralization, we have been pleasantly surprised to obtain these additional high-grade intersections. The pit sampling and historic drilling encountered lengthy high-grade zinc intercepts which have been further delineated by the drill program. The results attest to the robustness of Mina Grande Sur and will contribute to the upcoming resource calculation.”

Mina Grande Sur Drill Results Highlights:

- Results from 11 holes were reported previously (see news release from March 29, 2018)

- Significant new intercepts include:

- MGS18016 – 4.7 metres of 26.1% zinc, from surface

- MGS18017 – 8.2 metres of 42.7% zinc, from 7.5 metres drill depth

- True vertical thickness of 5.8 metres from true vertical depth of 5.3 metres

- MCH18020 – 20.5 metres of 34.3% zinc, from surface

- True vertical thickness of 14.5 metres

- Mineralization at Mina Grande Sur includes zinc oxides, carbonates and silicates hosted by soils, highly-weathered carbonates, and fine- to coarse-grained dolomites.

Geology and Discussion of Results

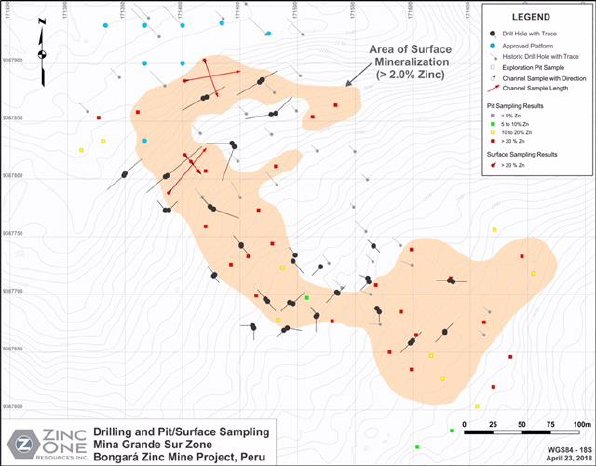

The zinc mineralization at Bongará is hosted by carbonate rocks and is classified as a Mississippi Valley-type deposit. The mineralization is stratabound and is basically a tabular body with irregular boundaries. Hydrozincite, smithsonite, hemimorphite, and a zinc-aluminum-iron silicate are the primary zinc minerals that are hosted primarily by soils, heavily-weathered fractured dolomites and dolomite breccias. Given that the strike and dip of the mineralization is not known, the intercepts do not necessarily represent true thicknesses; moreover, long intercepts, e.g., MGS18-003, most likely drilled subparallel to the dip of the tabular mineralized body. At Bongarita specifically, mineralization is exclusively hosted by soils. Overall, the mineralization is focused along the axis of a doubly-plunging anticline as well as within the eastern flank of the anticline.

Sampling and Analytical Protocols

Zinc One follows a systematic and rigorous Quality Control/Quality Assurance program overseen by Dr. Bill Williams, COO and Director of Zinc One.

The sample from each core run is placed in a 60-centimetre long, plastic core box that has five columns. Core recovery, rock quality designation (“RQD”), and geologic features are logged and sample intervals, which are generally <2 metres, are chosen. Each core box is photographed and then sampled with a spatula (soil and heavily-weathered rock) or cut with a core saw, 50% of which is placed in a sample bag and stored on site in a secure location. The Company independently inserts certified control standards, blanks, and duplicates, all of which comprise at least 20% of the sample batch, to monitor sample preparation and analytical quality. The samples are stored in a secure area until such time they are shipped to ALS laboratory in Lima (ISO 9001 Certified) for preparation and assay. At the laboratory, samples are dried, crushed, pulverized and then a four-acid digestion is applied. This is followed by the ICP-AES analytical technique for 33 elements, including lead. The same method is used to assay zinc for values up to 20%. If zinc exceeds 20%, it is then analyzed using a titration method. The laboratory also inserts blanks and standards as well as including duplicate analyses.

Qualified Person

The technical content of this news release has been reviewed, verified and approved by Dr. Bill Williams, COO and Director of Zinc One, a qualified person as defined by NI 43-101.

About Zinc One Resources Inc.

Zinc One is focused on the exploration and development of prospective and advanced zinc projects in mining-friendly jurisdictions. Zinc One’s key assets are the Bongará Zinc Mine Project and the Charlotte Bongará Zinc Project in north-central Peru. The Bongará Zinc Mine Project was in production from 2007 to 2008, but was closed due to the global financial crisis and concurrent decrease in the zinc price. Past production included >20% zinc grades and recoveries over 90% from surface and near-surface zinc-oxide mineralization. High-grade, zinc-oxide mineralization is known to outcrop between the mined area and the Charlotte Bongará Project, which is nearly six kilometres to the NNW and where past drilling intercepted various near-surface zones with high-grade zinc. Zinc One is managed by a proven team of geologists and engineers who have previously constructed and operated successful mining operations.

Additional Information

Monica Hamm

VP, Investor Relations

Zinc One Resources Inc.

Phone: (604) 683-0911

Email: mhamm@zincone.com

www.zincone.com

Forward-Looking Statements

Information set forth in this news release contains forward-looking statements that are based on assumptions as of the date of this news release. These statements reflect management’s current estimates, beliefs, intentions and expectations. They are not guarantees of future performance. Zinc One cautions that all forward looking statements are inherently uncertain and that actual performance may be affected by many material factors, many of which are beyond their respective control. Such factors include, among other things: risks and uncertainties relating to Zinc One’s limited operating history, its proposed exploration and development activities on the Bongará Zinc Oxide Project and the need to comply with environmental and governmental regulations. Accordingly, actual and future events, conditions and results may differ materially from the estimates, beliefs, intentions and expectations expressed or implied in the forward-looking information. Except as required under applicable securities legislation, Zinc One does not undertake to publicly update or revise forward-looking information.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the Exchange) accepts responsibility for the adequacy or accuracy of this release.