The rack serve carrier can easily be operated and is nevertheless efficient. If compared to area storage, performance is improved thanks to faster access to the individual types of boards on the rack.

Direct Access in the Warehouse

Restacking usually has to be done in area storages with building stacks up to 2 metres high in order to access the boards - a time-and-energy-consuming way. A job that now can be dispensed with.

With low piles in the rack system the rack serve carrier directly withdraws the board material. In this way a large variety of different types of boards can be taken from the rack without having to restack them.

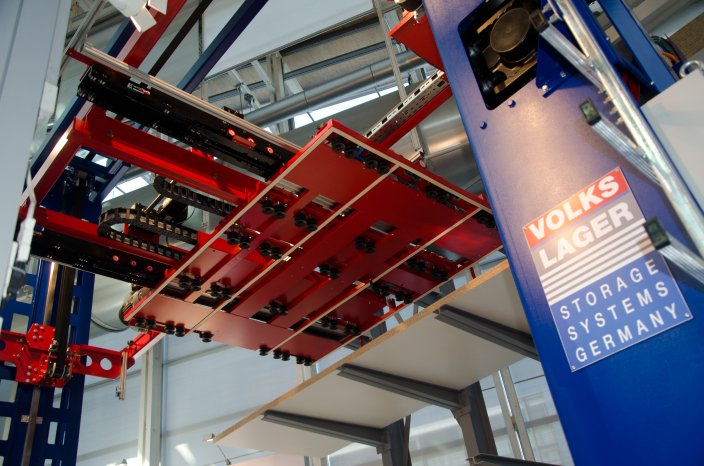

To remove them from stock, the individual boards are safely picked and then directly moved to the panel saw by a vacuum system that extends to both sides by means of telescopes.

Stack Transportation at the Lowest Level

Owing to the possible access to the lowest level now also the lower level can be served by using the integrated stack telescopes on the rack serve carriers' base frame. Complete stacks can be stored in the lower levels on each side of the aisle of the high bay storage.

In this way, the fast moving materials in the storage are also quickly stored in and out.

Furthermore commission stacks can be prepared by the rack serve carrier at the lowest level of the rack system. They can be taken out as a complete stack whenever this is needed.

Volkslager Presentation at LIGNA

SYSTRAPLAN is going to present a VOLKSLAGER with stack transportation at the forthcoming LIGNA, to be held in Hanover from 11. - 15. May.

SYSTRAPLAN will present themselves at the LIGNA in Hanover at its usual place in hall 26.