With increasingly high performance of mobile phones, notebook PCs, digital still cameras, portable DVD players, and other compact digital equipment and multi-functional electronic devices, there is an increasing need to take measures against EMC and noise. Noise can take the form of conductive noise transmitted along wiring and radiation noise transmitted through space. While conductive noise can be suppressed using capacitors or inductors, suppression of radiation noise requires wave absorption sheet or shielding materials that cut off radio waves. Conventional

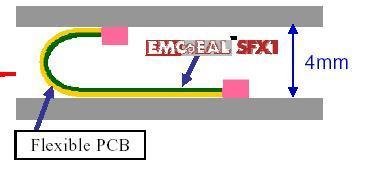

wave absorption sheets, however, could not be used in devices with frequent bending, and so could not be directly applied to sources of radiation noise on flexible PCBs that connect a display device or other movable parts and a motherboard.

In response, Taiyo Yuden combined its advanced materials technology with EMC evaluation technology to disperse a metallic magnetic powder with high permeability into an organic polymer binder with superior flexibility and reliability. It was further combined with a heat-resistant seal adhesive to result in successful development of the "EMSEALTM SFX1," a revolutionary electromagnetic wave absorbing film capable of attachment to curved areas.

Mass production of this product is to begin at the Haruna Plant (in Takasaki city, Gunma

prefecture) in December 2007, at a pace of 500m2 per month. Film appearance, dimensions, and thickness will be made to custom order (standard film thicknesses are 0.25, 0.35, and 0.55mm). Sample price is 20 yen per cm2 iprocessing cost separate).

This product will be on display at the Taiyo Yuden booth for CEATEC Japan, to be held starting October 2, 2007 at Makuhari Messe (Mihama-ku, Chiba city).

"EMSEAL" is a registered trademark of Taiyo Yuden.