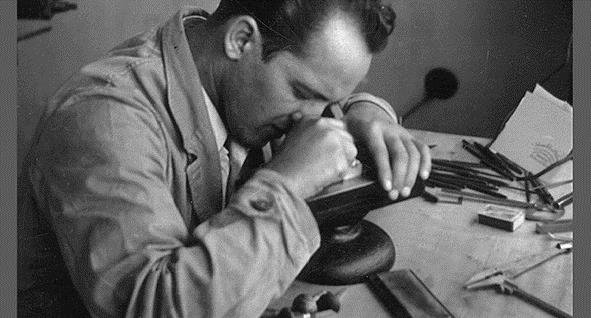

The success story starts 1956 with DM 500.00 (Deutsch Mark) starting capital. In Stuttgart, Wilfried Philipp, born 1928 in East Sudetenland (now Czech Republic), primarily engraves by hand printing plates for the precise relief print. The business grows fast. In 1961, together with 15 employees, "Wilfried Philipp Industriegravuren" moves into larger premises in Stuttgart-Zuffenhausen. That’s where Wilfried Philipp makes two ground-breaking inventions: The worldwide first hand-operated Pad Printing Machine and an automatic Engraving-Device for the manufacture of dies for coins and medals. With their application the first automations and the change from manufacture to industrial engraving operation was initiated. Rapidly the company sets bench marks. Because: It’s quality, reliability and speed is exceptional on the market.

Application of the Pad Print

The Pad Print is predominantly used for precise printing and decoration of technical components and consumer goods. But it is not quite that simple: As there are hardly any restrictions for the application of the Pad Print process, the possible uses of the TAMPOPRINT machines is virtually unlimited. From motifs on beverage closures to characters and symbols on switches, levers and keyboards. Clothing and faces, which characterise the entity of toy figures, as well as product information and logos, are printed on any type of product. Even lubricants in the motor construc-tion and medical agents in the pharmaceutical industry can be transferred. And the application spectrum grows daily!

In 1968 after "fiddling around" for a long time, Wilfried Philipp invented and patented the printing pad made from silicon rubber. This replaces the up to then customary gelatin pad. With this pad solvent-based inks can be used for the print, which allow printing with much higher speed. At the "K-71", the leading trade fair for the Plastics Industry in Duesseldorf, in 1971 the first electro-mechanical driven Pad Print machine is introduced. This marks the beginning of the industrial application of the Pad Print. Still during the trade show, enthusiastic customers place their first purchase orders and pave the way to the machine builder TAMPOPRINT.

TAMPOPRINT – a Synonym of the Printing Process

The advantages of the Pad Print are apparent: Small machines, resilient and easy to maintain. Tolerant against dust and dirt, and operational in almost any climate. But the unique characteristic of the Pad Print is: Almost any formed bodies can be printed distortionfree! This resulted that during the first decades illegal replicas (not protected by patent and traceable) flooded the market. Today almost 80% of the worldwide manufactured pad printing machines are located in the East Asian region. No wonder that Wilfried Philipp is deemed the icon of the Pad Print and the company name TAMPOPRINT as the synonym of the Printing Process.

With the invention of the closed ink systems HERMETIC (1983), the Rotary Pad Print (1981) and the pad printing machine SPEED (2010), TAMPOPRINT with their innovative inventions consistently advanced the Pad Print. In focus are always the factors Speed, Precision and Ease of Operation.

A Print Process conquers the World

The first and to this day ongoing foreign relation connects TAMPOPRINT with Japan. Already 1977 TAMPOPRINT fosters worldwide business connections and founds their sister companies, first in the USA, later in France and Spain, followed by the acquisition of today’s system supplier ALFA TOOLS and the intensive expansion of the global dealer network. The TAMPOPRINT Group counts approximately 300 employees and more than 40 agencies in foreign countries.

With Innovations at the Top

Right from the beginning and with the high intuition TAMPOPRINT develops machine- and complete automation solutions for the industry. In recent decades particularly multicolour Pad Printing machines and Rotary Pad Printing machines show high sales. But: Robust and durable products do not guarantee outstanding market position. Exceptional process know-how and a boundless will from the TAMPOPRINT Team master seemingly unsolvable customer requirements, make the company into the technology leader and "Enabler" in the field. At the beginning of 1990 TAMPOPRINT researches for a new kind of cliché material for the Pad Print. At that time the cliché production was handmade and the quality significantly dependent on the experience of the maker. The goal is therefore to produce exact reproducible printing images of highest quality. Very fast it became apparent, that the LASER Engraving was the perfect resolution. The procedure is independent from the operator and with precise parameters controlled from the computer. Since then TAMPOPRINT produces cliché material for raster and line engravings, which are optimized for LASER sources with low energy consumption. In the meantime even Ceramic and Chrome-Cliché Cylinders for the Rotary Pad Print are directly LASER engraved within minutes and exactly to customer’s requirements.

What is PAD PRINT?

With Pad Print the printing image is engraved or etched into the cliché plate., For the printing, the pad printing ink is distributed over the cliché and afterwards removed; therefore the pad printing ink only remains in the cavities. These ink remnants will be picked up by the pad and transferred onto the part to be printed. Therewith is the Pad Print an indirect gravure printing and it is the only printing process, with which print images are transferred distortionfree onto complex threedimensional bodies.

The Process in Center Stage

Over the years TAMPOPRINT has disengaged from the plain machine engineering. In the meantime 50% of the production volume consists of full automatic Pad Print Automation. In today’s center stage stands the optimal collaboration of machines, consumable material and the human as the operator. In short: Central aspects are quality and sustainability of the integral process. As a Top-A supplier of the industrial enterprises, TAMPOPRINT offers process dependability starting from the first meeting, over validated acceptance to the intensive support during operation. No matter if PAD PRINT or LASER Individualization.

In the year of the 60th Anniversary, Wilfried Philipp holds worldwide 232 patents and is with the TAMPOPRINT AG broadly positioned in all industry sectors. The new inventions of the coming years will furthermore revolutionize the market, and thanks to the highly motivated employees find the way into the manufacturing industry. Chairman Oliver Nitschke reckons: The challenges of the coming years are most likely in the individual product decoration. Our customers expect digital, parametric control processes and appreciate the networking of all relevant components of the complex production.

During the last years, the TAMPOPRINT AG made courageous steps forward, and were in return awarded with full purchase order books. A further three patents in 2016 and the attempt to manufacture all processrelevant components inhouse, ensure longterm the quality and reliability of the company. Totally in the sense of the first beginnings!