Headquartered in Bavaria, Germany, WISA Werkzeug- und Formenbau GmbH (WISA) is a medium-sized company that has carved out a respected position over the past 30+ years developing and manufacturing technically sophisticated tooling and molds for customers across a variety of industries, including automotive. Historically, the company exchanged drawings and parts lists with customers in paper form. Increasingly, however, the information they needed to successfully produce their complex tooling and molds was contained in 2D and 3D CAD files.

"The move away from paper towards digital files made it all the more important for every employee to be able to look at and access this data," explained Torsten Decker, Managing Director of WISA. "Not everyone who wants to check a few dimensions in a CAD file needs the full functionality of an expensive CAD tool, especially since it's not necessarily that easy to use either. In addition, customers provide us with data in a wide variety of formats, and we were sometimes unable to read them in - we needed to find a better way to handle visualization of CAD data.”

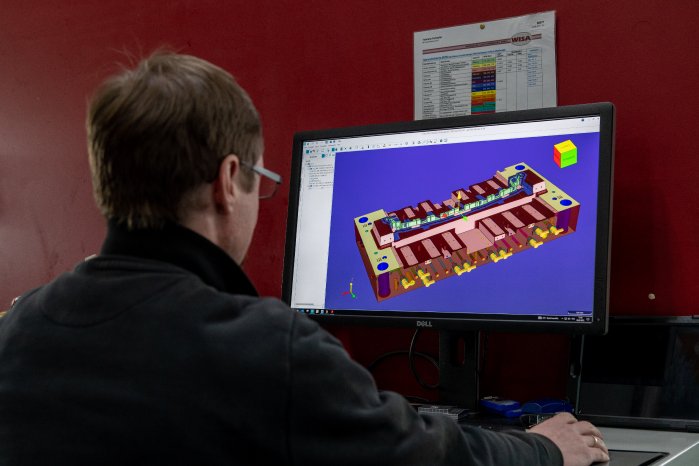

After thoroughly researching different CAD viewer offerings, the company quickly selected SpinFire from Actify as the best option. SpinFire gives teams everything they need to view and interrogate assemblies, parts, and drawings in all major 2D and 3D CAD formats. The tool not only visualizes design data, but also provides analysis tools with functions such as measurement, dimensioning, wall thickness analysis, exploded view, and markups, among others. Additionally, SpinFire converts CAD data into a compact, neutral format for easy sharing with internal and external teams.

Despite its powerful functionality, one of SpinFire’s key benefits is its intuitive, user-friendly nature. An introduction to the tool only takes 15-30 minutes, and the most important functions can be learned quickly – something that WISA’s teams have greatly appreciated. At first, WISA only used the software tool in the calculation and quotation preparation department. Later, a single license was added in the work preparation department, and additional licenses were added to other teams over time, depending on requirements.

The growing demand for the solution across the organization led the company to realize that the Enterprise version of SpinFire would make the most sense, allowing them to take advantage of a single enterprise-wide license. Now, every PC in WISA – from the purchasing and sales departments, to design and manufacturing – has a powerful CAD viewer that employees can leverage.

"We no longer need to handle licenses because a SpinFire Enterprise license covers an unlimited number of workstations at our company,” said Decker. “As a side benefit, this greatly reduces the administrative effort – which makes the IT department happy. That widespread deployment is important, because otherwise the chain is broken."

The importance of this “unbroken chain” across departments has been demonstrated multiple times, with one particular instance of helping a customer troubleshoot issues with their new molding tool helping to paint the picture.

"Before we could assist the customer, we had to really understand how the tooling worked,” said Decker. “That's where SpinFire helps us, with features like sectional views through the assemblies. Colleagues from the assembly and design departments looked at the 3D data together and sent the customer suggestions for optimizing his tool. Once these suggestions were approved, the design was modified in a CAD system. Finally, the team used SpinFire to add manufacturing notes to the 3D data and create screenshots for capacity planning. Everywhere you look, the tool has its fingers in the pie, so to speak.”

This type of widespread usage has resulted in more efficient workflows: nearly all tooling or mold information can be stored in the 3D CAD model and accessed via SpinFire. As a result, additional PowerPoint or PDF documents are no longer required, streamlining documentation efforts.

Design and production are hardly the only areas that benefit from SpinFire. The CAD viewer has also ensured greater accuracy around purchasing, making incorrect orders for materials much less frequent. The small file size of the 3D SpinFire data – and the associated minimal hardware requirements – provides another key benefit. This is particularly noticeable with very complex assemblies, such as those typical for WISA's injection molds.

“After saving a two gigabyte CAD file in the compact SpinFire file format, the file size is reduced to about 60 megabytes,” said Decker. “This makes it much easier to handle the data and exchange it with the customer. No matter what the customer sends us - we can read it in - That’s priceless.”

Ultimately, SpinFire Enterprise has made many aspects of WISA's daily work easier and more efficient, from licensing and customer communication, to troubleshooting and material planning. Most important, however, is the reliable and cross-departmental availability of 3D visualizations.

To learn more about Actify SpinFire Enterprise, visit https://actify.com.