However, the low density of the hydrogen requires comparatively large opening cross sections to blow the gas into the combustion chamber in the available time window. In addition, the dry gas has no lubricating properties whatsoever. At present, there are no mass-produced LP-DI injectors that can meet the specifications in the long term.

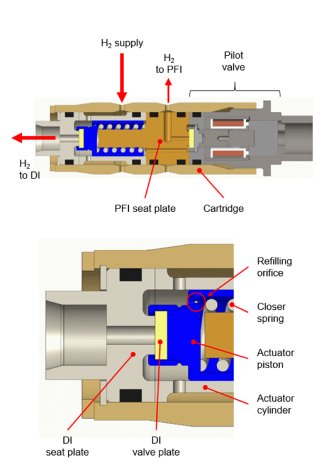

The Heilbronn scientists led by Prof. Karsten Wittek have developed a novel LP-DI system for gaseous fuels. It is based on an inward-opening nozzle with a seat seal. The sealing element is actuated servo-pneumatically and uses the pressure energy of the inflowing fuel gas. The design of the seat geometry in combination with highly wear-resistant ceramic materials also guarantee compliance with the demanding service life requirements of industrial applications. The system is particularly suited for large engines such as those of heavy commercial vehicles, construction machinery, locomotives and GenSets.

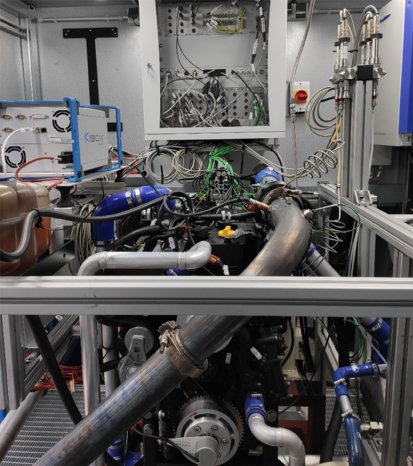

The concept was realized as a prototype and extensive series of tests were completed on the injection nozzle test bench and on the engine test bench. All relevant functional properties could be confirmed experimentally.

A detailed scientific presentation and discussion of the test results can be read in the technical publication (link: https://doi.org/...).

A patent application was filed for the invention, which has since been granted (DE 10 2020 127 020 B3). Technologie-Lizenz-Büro (TLB) GmbH supports the scientists and Heilbronn University of Applied Sciences in patenting and marketing the current development. TLB is in charge of the exploitation of this pioneering technology and offers licensing opportunities to engine manufacturers.

For further information: Innovation Manager Benjamin Schilling, M.Sc. (schilling@tlb.de).