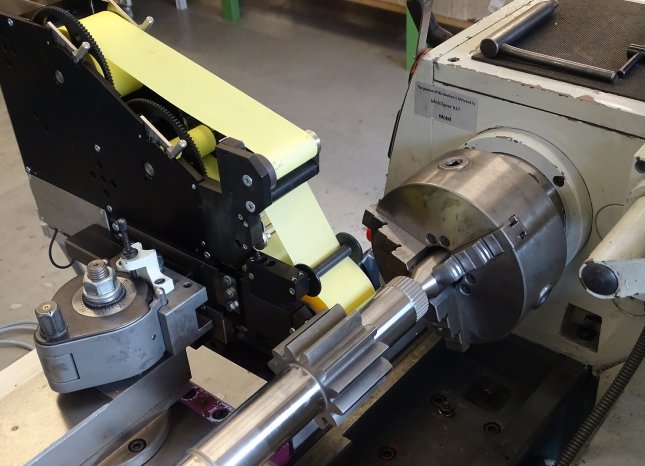

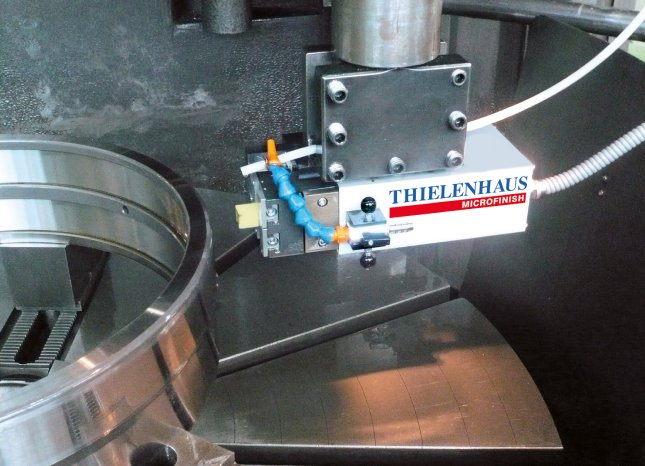

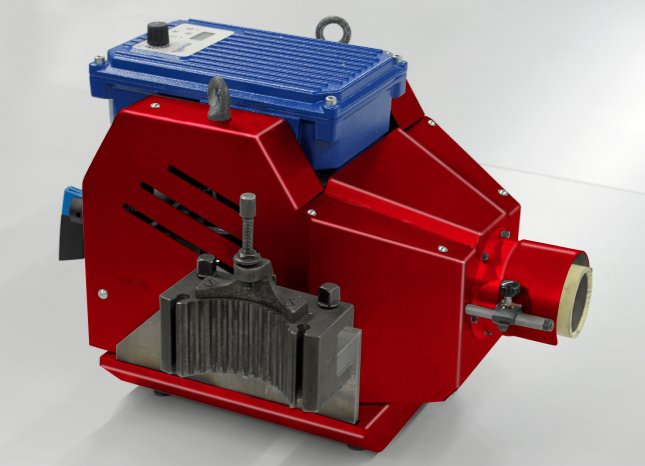

All of the attachments consist principally of an electric drive unit for high short-stroke movements and the oscillating tape or stone tool. The workpieces are held in the base machines between centres or, if no centering bore is present, tensioned from one side with a chuck or a collet. For the machining, they are set in rotation, with the oscillating stone or tape tool being pressed onto the workpiece pneumatically or using spring tension. The removal, which is performed in a sine-wave form due to the oscillation, removes the ‘soft layer’ generated during the hard turning or grinding process, drastically improving the roughness and contact ratio. Using this process, surface roughnesses of Ra 0.01 µm with rolls and Ra 0.3 µm with bearing positions can be achieved. At the same time, the surface can be given a structure with defined, criss-crossing grooves to improve its tribological properties.

Even though they’re small and good value for money, the devices are nevertheless high-performance units geared towards three-shift operation. They are principally used for geometrical improvements in roundness, evenness and cylindrical forms. Surfaces can also be smoothed to a mirror finish and definable levels of roughness can be produced. The residual compressive stress can also be raised in order to make the surface more wear-resistant. As well as chamfering edges and smoothing joints, the attachments can be used to achieve visual, cosmetic surface textures.

Microfinish attachments are particularly suited to the small batch sizes typically found in the production of hydraulics rods, components, sealing seats and shaft sleeves. However, larger individual workpieces such as calender rolls, cold rolls, Sendzimir rolls and printing rolls can be worked to a mirror finish. Foil manufacturers, for example, require mirror-finish surfaces; the printing industry needs precisely defined printing rolls in order to guarantee precise colour distribution, and hydraulics/pneumatics manufacturers need finely structured surfaces with a large contact ratio and twist-free sealing surfaces. Our competitively priced attachments are ideal for use wherever precisely defined and structured surfaces are required for small batch sizes.

Since the attachments can be used with many different base machines and special equipment, the workpieces are not dimensionally limited. Their form can be that of a flat surface, start-up shelves, external or internal rotationally symmetrical surfaces, but it can also be that of excenters, cams or cam discs. Further uses also include those involving spherical surfaces such as radii and undercuts.

These attachments represent a cost-efficient opportunity to receive an entire application from the market-leading specialists in ultraprecision machining that gets you the desired results without long trial periods.

More information can be found at: Thielenhaus Technologies GmbH, Postfach 201855, 42218 Wuppertal, Germany, Telephone + 49(0)2 02 481-0, Fax + 49(0)2 02 45 04 45, or at www.thielenhaus.com