Sophisticated parts for the automotive industry

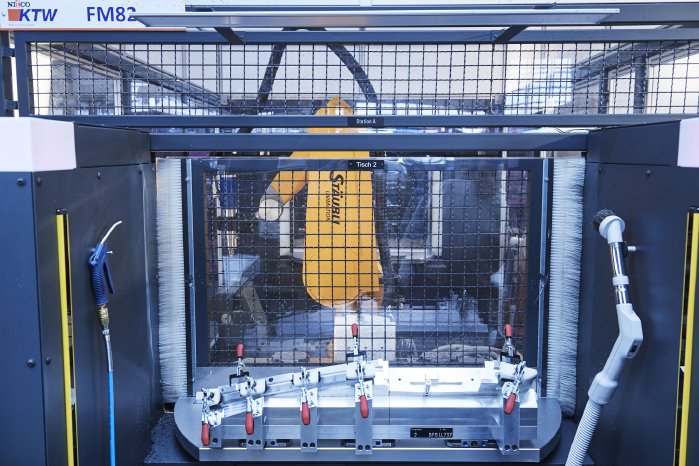

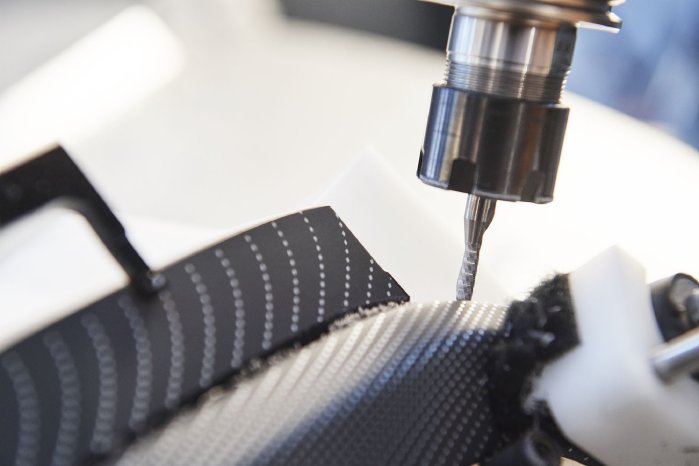

The objective was for the plastic parts, which are produced using 3K injection moulding and reinforced with around 20% fibreglass, to be processed using a robot. The parts are between 200 mm and 1,000 mm in size and the robot must achieve a precision of +/- 0.1 mm. Further requirements taken into account when constructing the robot cell included the integration of tool management and a tool changer. The robot, a Stäubli RX 160, as well as the tool changer form a single unit. Two rotary tables are positioned at an angle of 180° and give the cell flexibility. A complete casing makes the cell safe to use and rounds-off its design. It is able to accommodate eight different components (RFID) and boasts an integrated chip extraction feature. Toolcraft also took care of the offline programming.

Process reliability and precision

Since the components are visible after installation and gap dimensions need to be accurate to a tenth of a millimetre, the entire process must be reliable and precise. The combination of tool management, measuring systems and component recognition is essential for enabling the requirements to be met consistently throughout the processing procedure. Ensuring a compact yet user-friendly design presented an additional challenge when constructing the cell. Moreover, toolcraft made sure that freeform surfaces can be programmed to make them suitable for processing by the robot. It is also possible to make adjustments and corrections in the event of component warpage. The company’s longstanding experience in manufacturing machinery proved invaluable during this project. The team worked with software company unicam to program the robot.

Complete tailored solution from A to Z

After feasibility analysis, a test phase on toolcraft’s own robot cells followed. The integrator managed full construction and assembly. Including the time required assembling the system at the client’s premises, the solution was up and running within 16 weeks. The close collaboration with the client meant that the bespoke solution left no stone unturned.